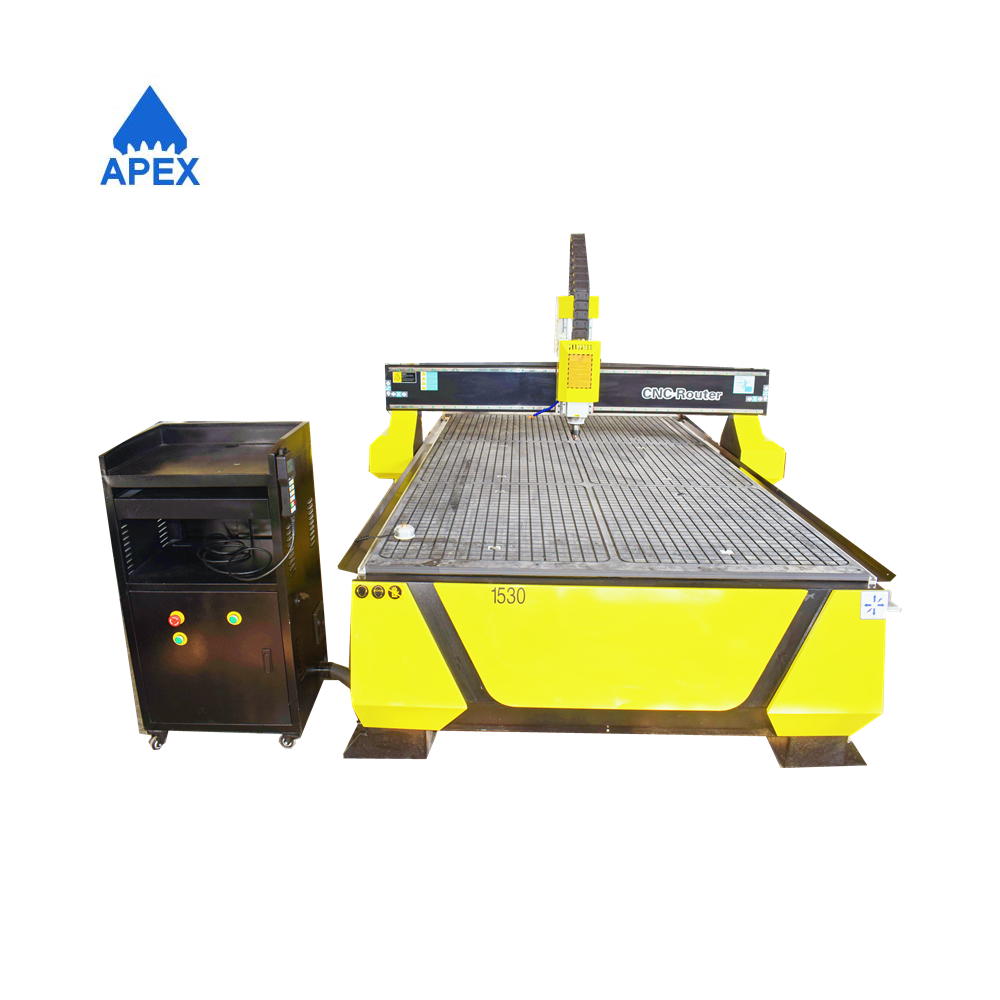

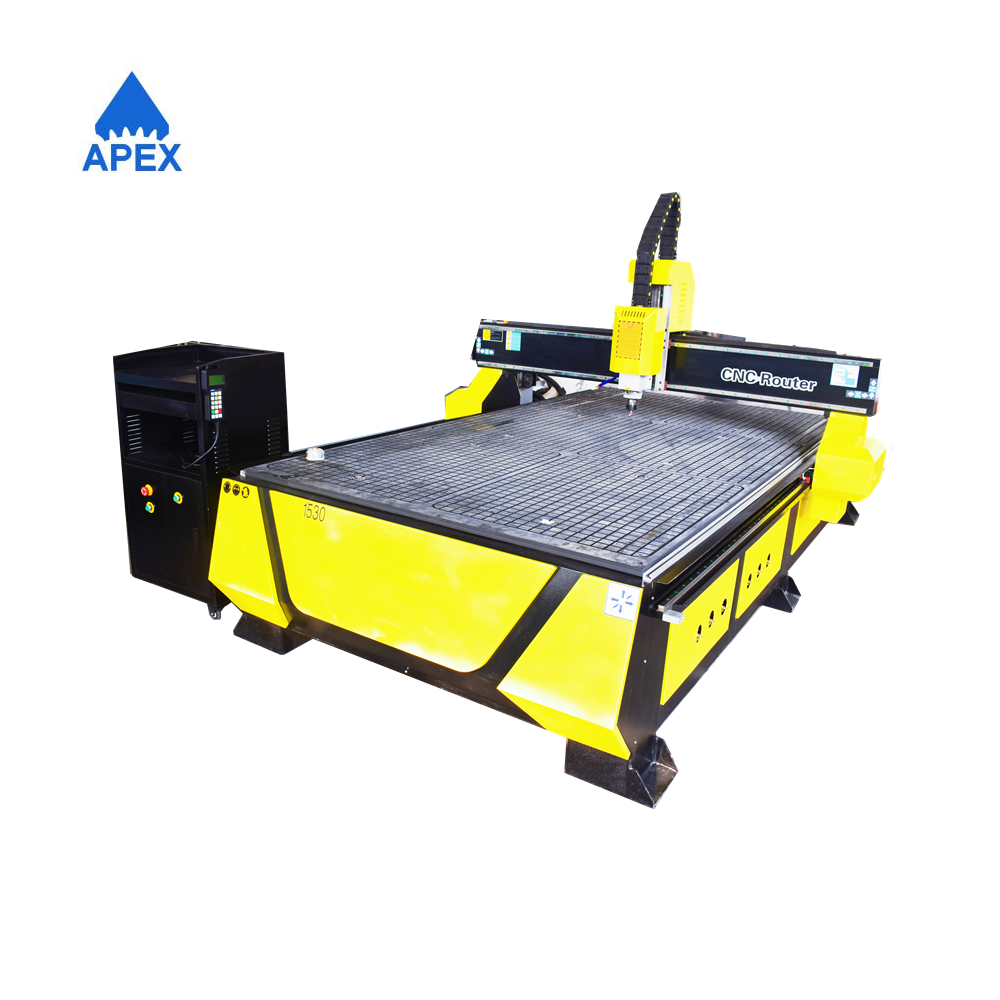

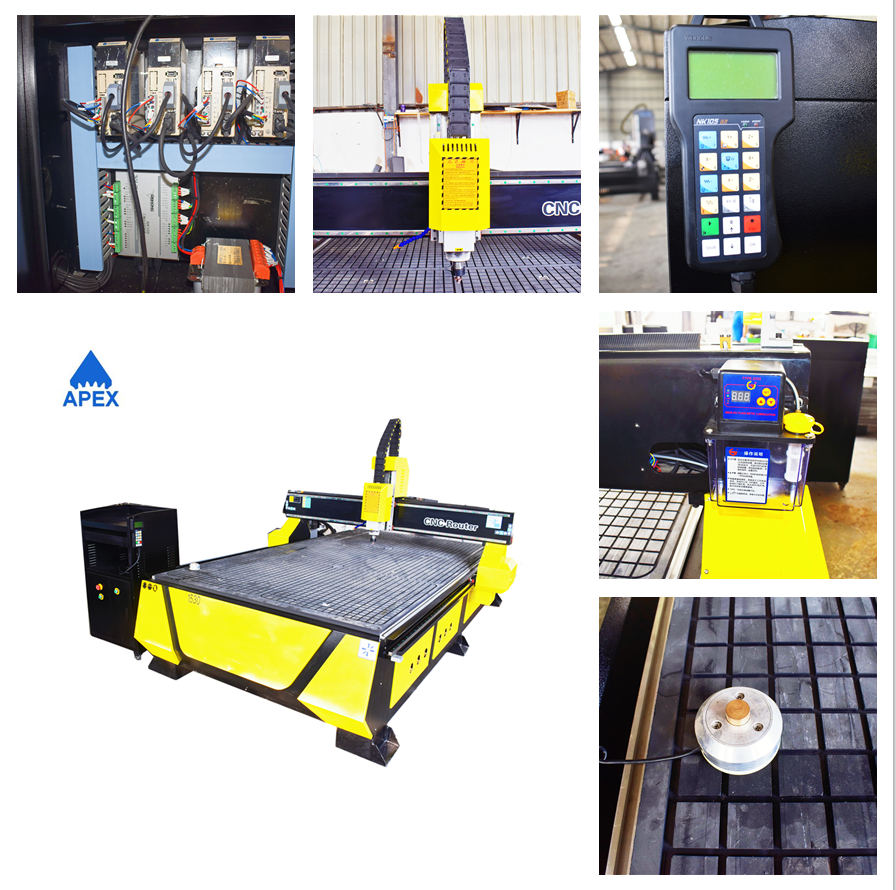

China CNC Manufacture 1530 wood cutting machine for wood furniture

Main features

1) DSP control system: Popular and easy operation, with USB port to transfer program;

2) China high quality air-cooling Spindle: Long working life, easy maintenance;

3) Big Stepper Driving Motor: With highly control precision and high speed, reliable and stable;

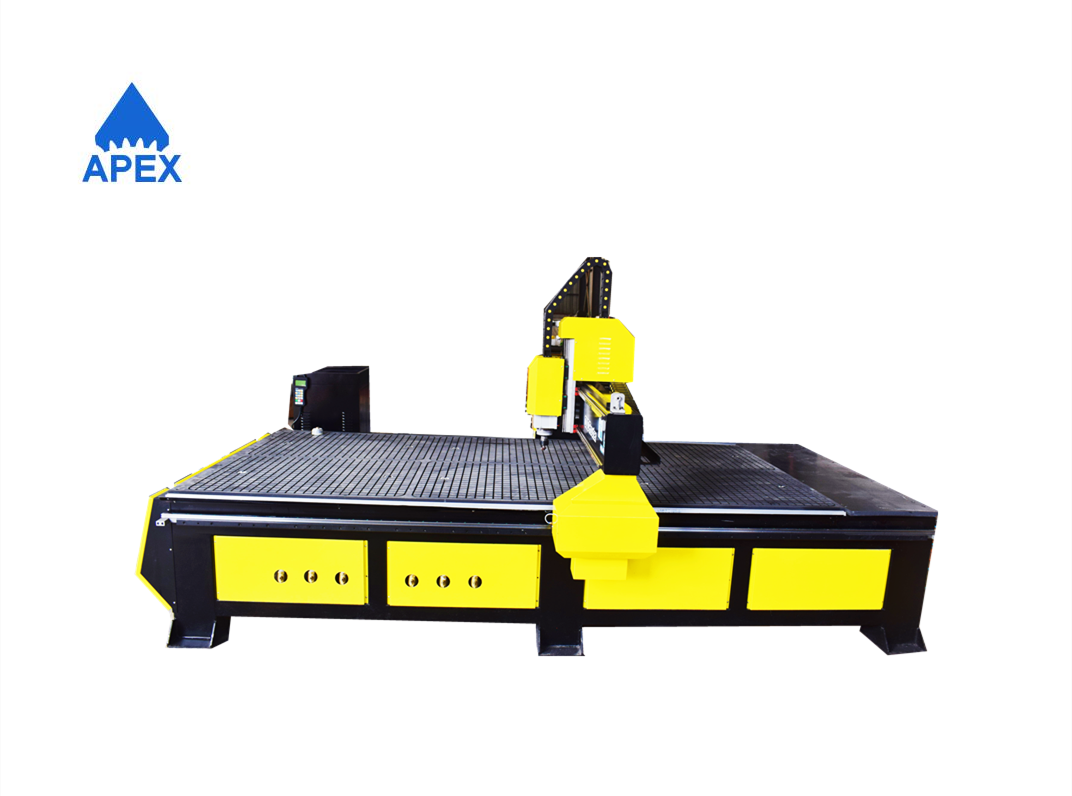

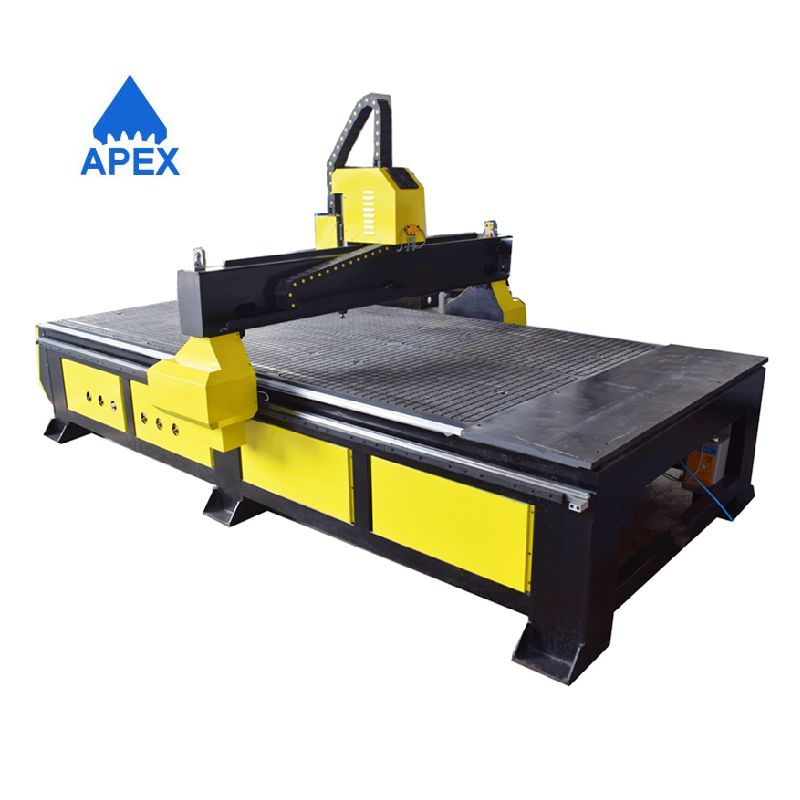

4) Taiwan Hiwin Guide and Block: Guaranteed genuine rail with good quality, realizing smooth movement;

5) Taiwan TBI ball screw: linear motion with high precision and and in high speed

6) Helical rack and pinion: quiet running, greater accuracy, smoother cutting and allows greater acceleration and feeding rates,

longer lifetime because of smaller wearing force.

7) Fuling Inverter: Guarantee the variety working speed and protect the spindle very well.

Technical Data:

| Description | Parameter |

| Model | APEX1530 |

| X,Y,Z working area | 3000* 1500* 200mm |

| Resolution | ±0.03/300mm |

| Repeatability | ±0.03mm |

| Table Structure | Vacuum table |

| Lathe Structure | Welding steel structure |

| X,Y structure | Rack pinion, Hiwin linear rails |

| Z structure | TBI Ball screw, Hiwin square rails |

| Max. rapid | 32000mm/min |

| Max. Working speed | 25000mm/min |

| Spindle power | 4.5Kw air spindle |

| Spindle speed | 0-18000RPM |

| Working mode | Stepper or servo |

| Working voltage | AC380V/50/60Hz,3Ph(Option 220V,3Ph) |

| Command code | G code |

| Operating system | Mach3 system (Ncstudio, Syntec,DSP ) |

| Interface | USB |

| Memory | 128M |

| Tool holder | ER25 |

| X,Y working accuracy | <0.03mm |

| Software | Artcam, Type3 UcancameV9 |

| Working temperature | Temperature:0 degree-45 degree Humidity:30%-75% (No Condensation) |

| Optional Spare Parts | Air-cooling spindle |

| Double bag dust collection,vacuum pump | |

| rotary |

Samples:

#Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

#The wood products: voice box, game cabinets, computer tables, sewing machines table,instruments.

#Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti bate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds.

#Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper engraving and milling process.

Samples:

#Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

#The wood products: voice box, game cabinets, computer tables, sewing machines table,instruments.

#Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti bate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds.

#Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper engraving and milling process.

Question 1:How long about the machine’s guarantee ?

Answer :2 years

Question 2:How about your after service ?

Answer :Technical support by phone, e-mail or MSN around the clock.

Question 3: How can we install the machine?

Answer :Friendly English version manual and operation video CD disk.

Question 4: How about the payment terms?

Answer:30% T/T for deposit, 70%T/T paid before shipping.

T/T, West Union, Paypal

Question 5: Do You Arrange Shipment For The Machines?

Answer: Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you.

For EXW price, clients need to arrange shipment by themselves or their agents.