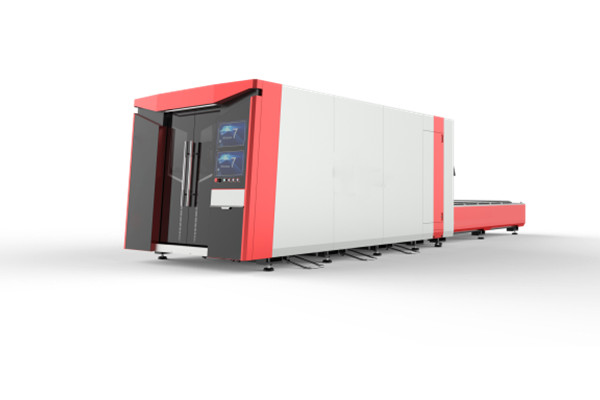

China CNC Manufacuture Sheet Metal Plate and Pipe CNC Fiber Laser Cutting Machine for Sale

Features:

1, high rigidity of the machine tool bed, exclusive high temperature control standard furnaces annealing treatment, can guarantee the precision of the machine tool is stable for a long time does not change.

2,Imported original fiber laser generator with good beam quality, stable performance, no reflector lens, no need to adjust the optical path, basic maintenance free, service life can reach more than 10 hours;

3, fiber laser with high Electro-optical conversion efficiency, conversion efficiency of 30%, the power consumption can be saved greatly when working.

4, Adopts imported original guiding drive and servo motor, high precision, high speed;

5, Supported all kinds of graphic format or text instant cutting, simple operation, flexible and convenient.

6, Beautiful, smooth cutting edge,without deformation;

7, low energy consumption, energy saving and environmental protection, low power consumption, the power consumption is VAG with the power consumption of 1/3-1/5, cutting speed of YAG is more than three times;

8, without working gas lasers, air available for sheet cutting ;

9, fast cutting speed, low operation cost,investment recovery quickly;

| Working Area | 1500*30000mm |

| Laser Power | 1000W/1500W/2000w |

| Laser Wave Length | 1064nm |

| Working Table | Fixed Working Table / Pallet Changer |

| Maximum Idle Running Speed | 1400mm/s |

| Position Accuracy | ±0.01mm/m |

| Moving Speed | 60m/min |

| Minimum Line Width | ± 0.02mm |

| Control System | Cypcut |

| Position Type | red dot |

| Power Consumption | ≤12KW |

| Working Voltage | AC220V ± 5% 50 / 60Hz / AC380V ± 5% 50 / 60Hz |

| Auxiliary Gas | oxygen,nitrogen,air |

| Laser Head | Precitec / Raytools |

| Protection System | Enclosure protection |

| Focus lens | Lasermech made in USA |

| Driver system | Japanese YASKAWA servo system |

| Liner guider system | PMI H series linear guide made in Taiwan , |

| Transmit system | Dual Rack & Pinion type |

| Chain system | Igus made in Germany |

| Warranty time | Whole machine for 3 years (fiber module 2 years ) |

| Gross weight | 3000KG |

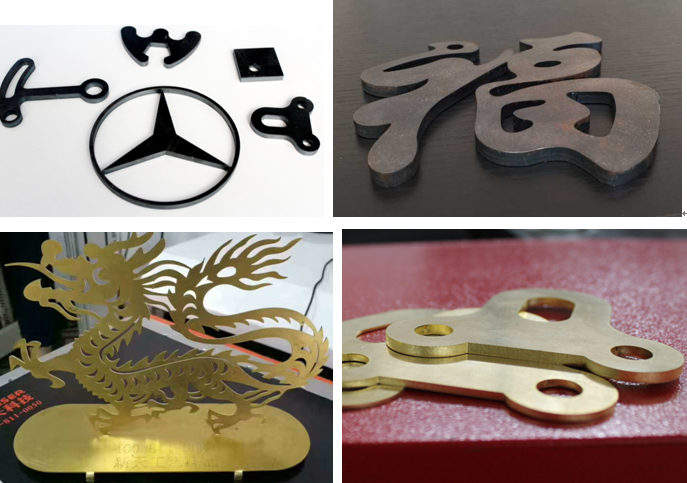

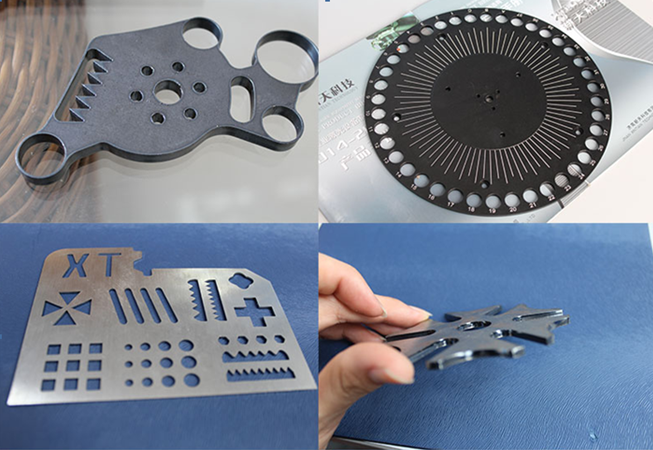

Application

Stainless Steel Laser Cutting Machine with 1000 watts fiber laser is applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Package&Shipiing

1. Strong water resit bottom in plywood.

2. Metal laser cutting machine parts with separated plywood case.

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard protective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Other Fiber laser cutting machine