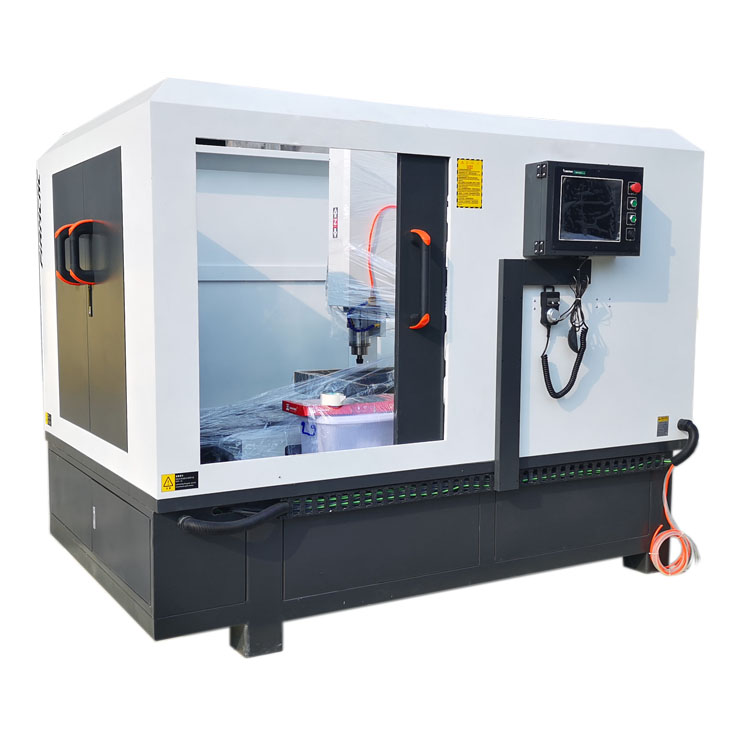

6075 Hot sale CNC Moulding Machine with Automatic Tool Changer

CNC moulding machine with automatic tool changer is a type of CNC router machine for molding, now the CNC moulding machine for sale at an affordable price.

Demonstration Video

Product Descriptions

Features of CNC moulding machine with automatic tool changer:

1. CNC moulding machine is the product of the combination of numerical control technology and engraving and milling process. It is a kind of multi-functional CNC machine. Similar to the ordinary numerical control machine, our metal engraving machine price realizes the carving, the milling processing automation through that numerical control system controls the engraving and milling machine movement according to process procedure code.

2. Stable and rigid structure: With the gantry type bed and table are one, it is not only good rigidity, but also no installation error for both,. Processing precision will not be affected even if being used for long time.

3. CNC moulding machine is a kind of fully enclosed design, it adopt external circulating cutting oil processing way.Machine body is fully casting with stable structure and great weight-bearing ability.

4. Machine has been equipped with accurate bidirectional ball screw of famous brand, Taiwan square rail and accurate bearing with strong rigidity and high dynamic accuracy. It is also equipped with Japan YASKAWA ac servo motor with high accuracy and high power make amplitude smaller and three-axis more stable.

5. CNC moulding machine has been equipped with automatic tool changer system.

Advantages of CNC Moulding Machine with Automatic Tool Changer:

1. Gantry structure: Whole cast-iron structure,steady structure,high rigidity ,precision 0.01mm. The double column is whole part, greatly increase machine rigidity.

2. Adopt high-speed water cooling variable frequency motor ,big torque,strong cutting ,high-frequency ,long-lifetime,can be a long time continuous working.

3. Cooling system: Oil circulating oil cooler for spindle, cooling workpieces with water or oil in the tank or atomization liquid through or spray nozzle.

4. Quality assurance: Each device before leaving the factory, we will test the cue with laser interferometer.

5. Servo motor and drives: from Japan with high precision and long life.

6. HIWIN linear guide: made from Taiwan,used for linear reciprocating stadium.

7. Three axis all use Germany ball screw and Taiwan linear orbits to make sure the accuracy and reposition precision.

8. Functional and easy-to-operate control system made by Taiwan SYNTEC with high performance and competitive price.

9. Adopt table movement to keep stable and high precision.

10. Enclosed work space ensures safe and contamination-free work.

11. Automatic tool changing system with 4 tools.

Technical Parameters of CNC Moulding Machine with Automatic Tool Changer:

| Performance index | APEX6075 |

| X,Y working area | 600×750mm |

| Z working area | 200mm |

| Max travel speed | 4m-5.5m/min |

| Max engraving speed | 2m-3m/min |

| Resolution ratio | 0.005mm |

| Repositioning precision | 0.01mm |

| Max feeding heigh | 150mm |

| Command | G Code *.mmg*.plt |

| Surroundings for software | windows98/2000/xp |

| Power | AC220V/60Hz |

| Main axle power rate | 1.5kw Constant Water Cooling Spindle |

| Spindle speed | 0-24000rpm/min |

| Work Mode | Servo system |