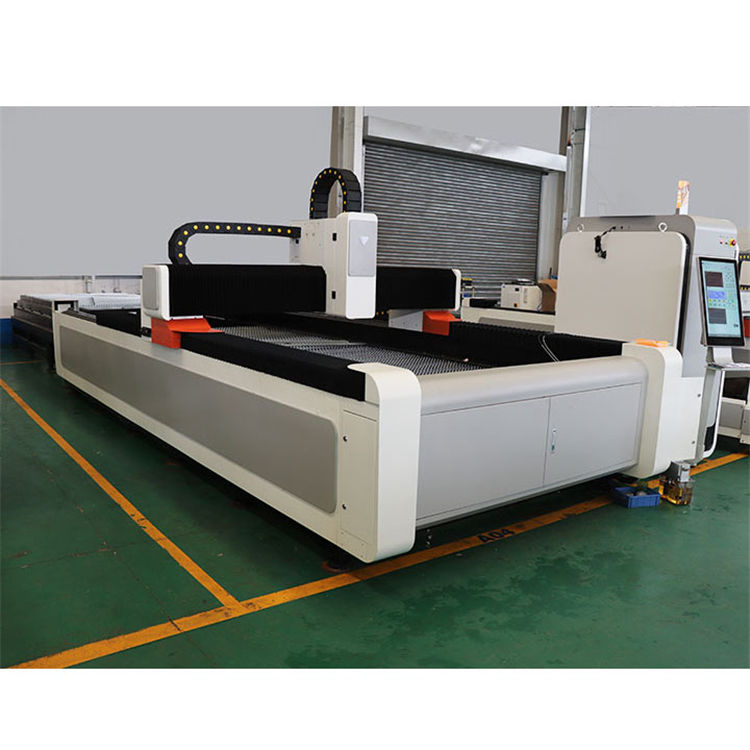

Factory For Laser Wood Engraver Machine - Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe – Apex

Factory For Laser Wood Engraver Machine - Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe – Apex Detail:

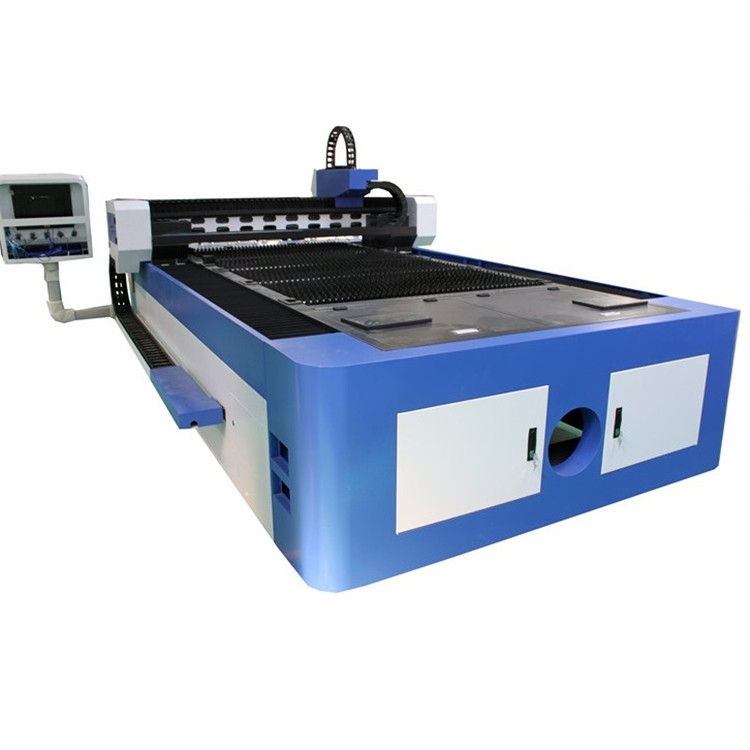

Fiber laser cutting machine has dual function for cutting sheet metal/metal plate and metal tube/metal pipe, such as steel, aluminum, alloy, titanium, copper, brass, iron and other metal materials.

Product Descriptions

Features and advantages of Dual-Purpose fiber laser cutting machine for Metal Sheet, Tube and Pipe:

1. The machine is equipped with an exchanged double working platform. While working on one table, the other platform can load and unload the sheet workpiece;

2. Auto feeding model is driven by frequency conversation drive-down motor, high transmitting power and safety factor, enabling stepless speed adjustment for different operating frequencies;

3. Pipe cutting machine is specially designed for metal pipes, metal tubes;

4. Imported high precision transmission device which is perfectly work with servo system, thus it can make sure cutting precision and efficiency;

5. Higher cutting quality and efficiency ,cutting speed is up to 120m/min with appearance and beautiful cutting edge.

Technical Parameters of Dual-Purpose Fiber laser cutting machine for Metal Sheet, Tube and Pipe:

| Model | APEX3015 |

| Laser Cutting Area | 1500*3000mm |

| Laser Power | 1000W (2000W, 3000W, 4000W, 6000W, 8000W for option) |

| Max Cutting Speed | 120m/min |

| Repeated Positioning Accuracy | 0.02mm |

| Power Requirements | 380V/50Hz/60Hz |

| Machine Weight | 8000KG |

| Machine dimension | 8950*3650*2350mm |

Applications of Dual-Purpose Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe:

Applicable materials: stainless steel, carbon steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron and other metal materials.

Applicable industries: Kitchen appliance, electric control box, high-resolute device, mechanical equipment, electrical equipment, lighting, posters, auto parts, display equipment, hardware and other metal processing.

Dual-Purpose Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe Projects:

Package for Dual-Purpose Fiber Laser Cutting Machine:

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard protective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Pre-Sale Service for Dual-Purpose Fiber Laser Cutting Machine:

1. Free sample cutting service:

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

2. Progressing Solution Design:

According to customer

Product detail pictures:

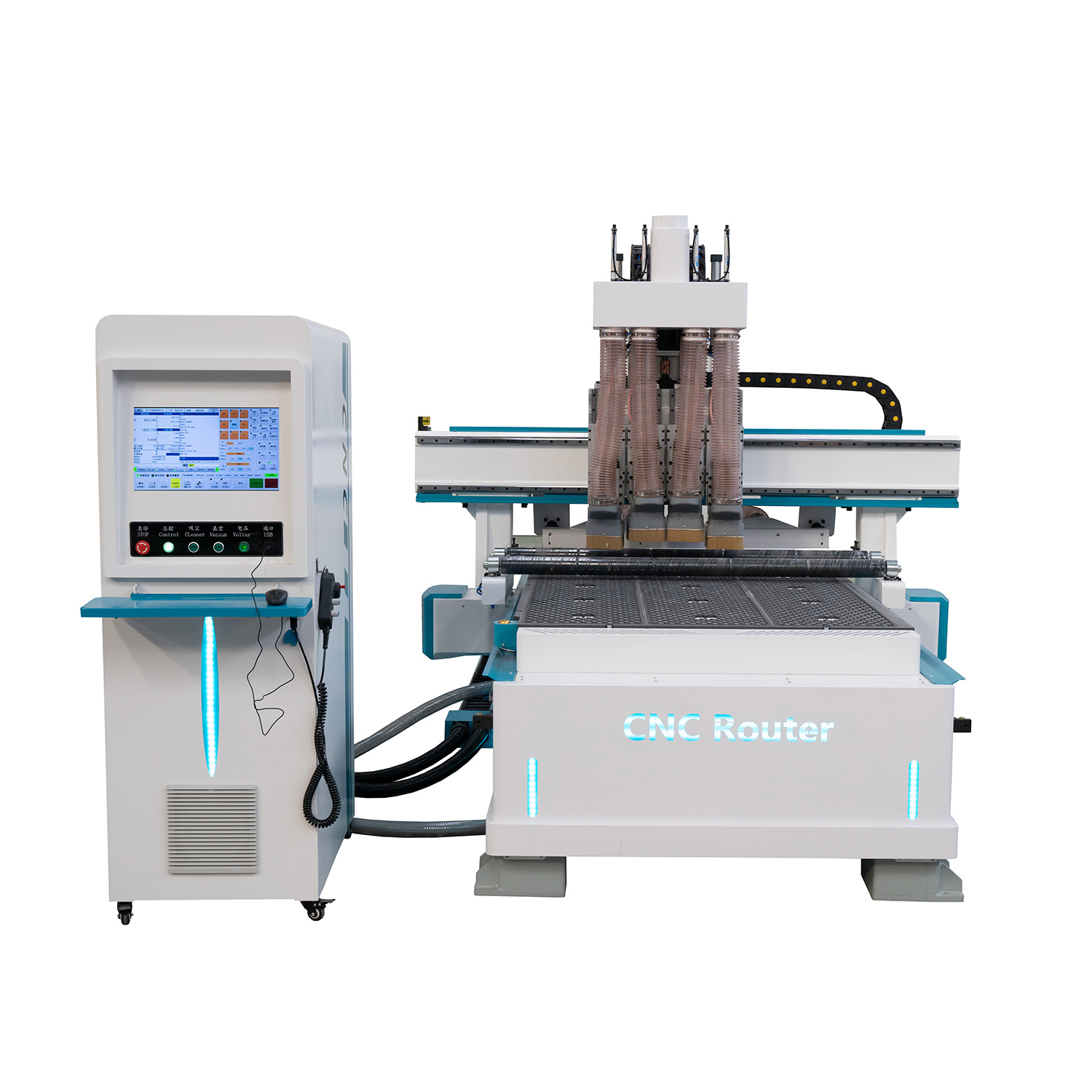

Related Product Guide:

We pursue the administration tenet of "Quality is superior, Services is supreme, Standing is first", and will sincerely create and share success with all customers for Factory For Laser Wood Engraver Machine - Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe – Apex , The product will supply to all over the world, such as: United States, San Diego, Riyadh, Due to the stability of our products, timely supply and our sincere service, we are able to sell our products not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We will do our best to serve your company, and establish a successful and friendly cooperation with you.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!