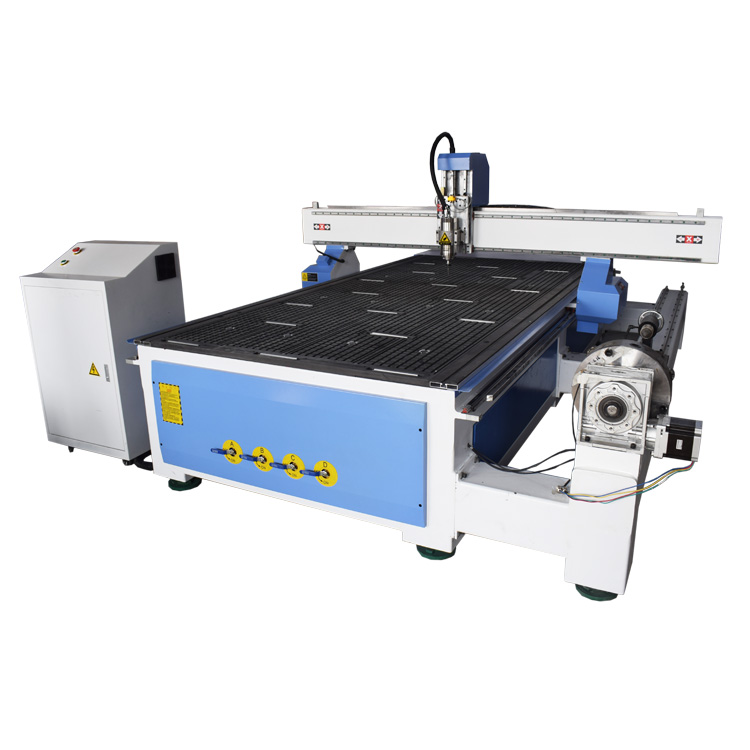

Fast delivery Wood Shop Cnc Machine – 4 Axis Atc CNC Router Wood Engraving Cutting with Automatic Tool changer – Apex

Fast delivery Wood Shop Cnc Machine – 4 Axis Atc CNC Router Wood Engraving Cutting with Automatic Tool changer – Apex Detail:

4 Axis Atc CNC Router Wood Engraving Cutting with Automatic Tool changer is used for side slot milling, drilling, cutting and keyhole, the 4 axis CNC router adopts 9KW HSD automatic tool changer spindle with 8 position rotary carousel tool holder, which is suitable for processing on different?surface.

Product Descriptions

Advantages of 4 Axis CNC wood router:

1. Big steel tube welded structure, after aging and tempering treatment, reliable and stable and not easy to deformation.

2. Top-quality components, HSD 4 axis ATC spindle, Delta inverter, TBI ball screw, Yaskawa servo motors, Syntec control system and so on. Long-time working time, high precision and efficiency.

3. Carrousel Tool Magazine system with 8 forks and tool holders , which is loaded with the spindle, make the 4 axis wood CNC machine change tools quickly and save time.

4. Many optional configuration and OEM service available. According to your requirement, different configurations will be offered.

Features of 4 Axis CNC wood router:

1. HSD spindle: original famous brand from Italian, you also can choose Hitech spindle and Chinese HQD spindle.

2. SYNTEC control system: from Taiwan with high performance and competitive price.

3. Yaskawa servo motor and drives: from Japan with high precision and long life.

4. HIWIN linear guide: from Taiwan, it is used for linear reciprocating stadium.

5. Working area: 1300*2500*400mm, C Rotary Axis: 180 degree.

6. Whole welded steel structure thicken to 10mm.

7. Drive System: X, Y-Rack Z-Ball Screw, Z with high precision ball screw.

8. Automatic lubrication: To lubricate rail and slide block , make it run better.

9. Schneider electrical components: original brand from France.

10. Japanese Omron Switch with long life.

11. Shimpo Reudcer from Japan: More powerful and higher precision.

12. Vacuum & T-Slot table with Aluminum sheel: Use vacuum pump and clamp fixed materials.

Technical Parameters of 4 Axis CNC Wood Router:

| Description | Parameter |

| X,Y,Z working area | 1300x2500x300mm |

| Table size (mm) | 1450×2940mm |

| Resolution | ±0.03/300mm |

| Repeatability | ±0.03mm |

| Table Structure | T-slot and Vacuum combined |

| Lathe Structure | Welding steel structure |

| X,Y structure | Rack pinion, Hiwin linear rails |

| Z structure | Ball screw, Hiwin square rails |

| Rated power | 3Kw (without spindle) |

| Max. rapid | 33000mm/min |

| Max. Working speed | 25000mm/min |

| Spindle power | 9.0kw Italy HSD Spindle |

| Spindle speed | 0-24000RPM |

| Working mode | Japan yaskawa servo motor and drivers |

| Working voltage | AC380V/50/60Hz,3Ph(Option 220V,3Ph) |

| Command code | G code |

| Operating system | Syntec controlling system |

| Interface | USB |

| Memory | 128M |

| Tool holder | ER25 |

| X,Y working accuracy | <0.03mm |

| Software | Type3 UcancameV9, Artcam |

| Working temperature | Temperature:0 degree-45 degree Humidity:30%-75% (No Condensation) |

| Packing size | 3300X2100X2300mm |

| Net weight | 1750KG |

| Gross weight | 1980KG |

| Optional Spare Parts | Domestic water cooling spindle |

| Double bag dust collection,vacuum pump | |

| rotary |

Product detail pictures:

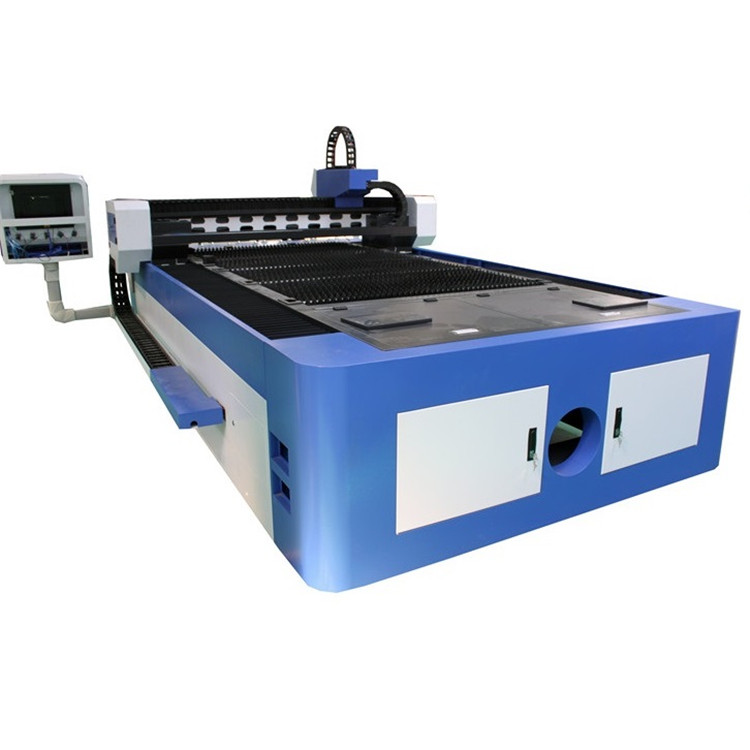

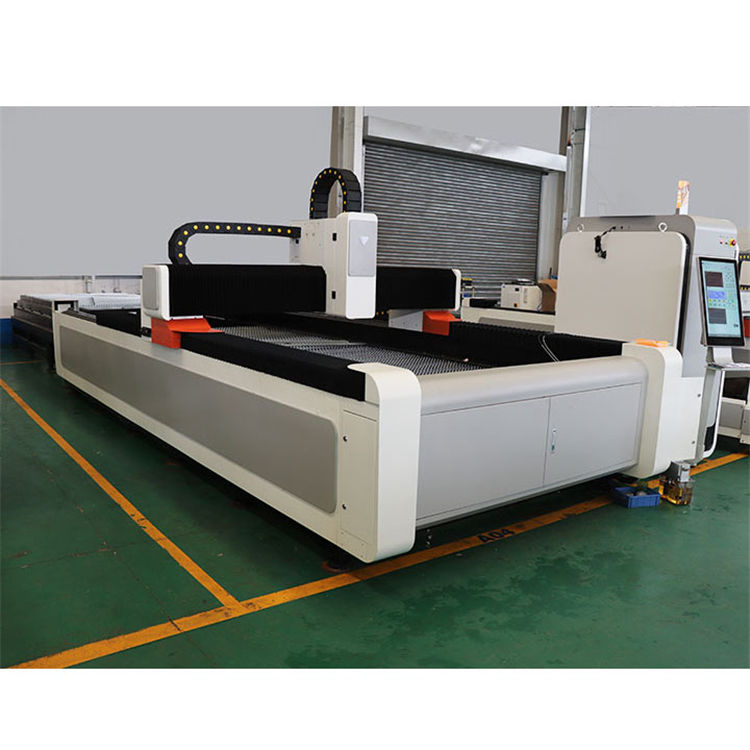

Related Product Guide:

Innovation, excellent and reliability are the core values of our firm. These principles today more than ever form the basis of our success as an internationally active mid-size corporation for Fast delivery Wood Shop Cnc Machine – 4 Axis Atc CNC Router Wood Engraving Cutting with Automatic Tool changer – Apex , The product will supply to all over the world, such as: Paris, Swansea, Turin, We warmly welcome you to come to visit us personally. We hope to establish a long-term friendship based on equality and mutual benefit. If you want to get in touch with us, please do not hesitate to call. We will be your best choice.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!