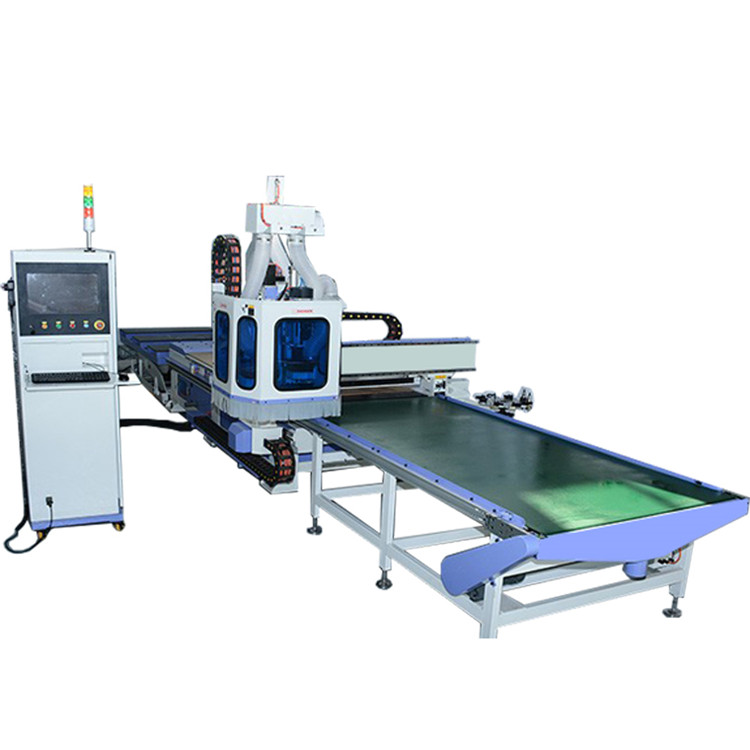

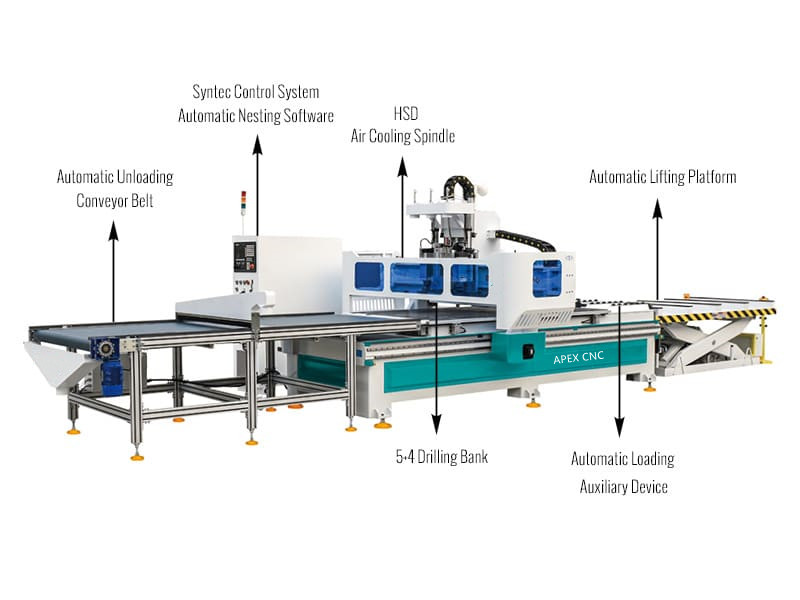

Full Automatic CNC Router for Furniture Making OEM & ODM

Full automatic CNC router is widely used in modern furniture making including customized panel furniture, cabinet making, home decoration, home door, home furniture, shop and office furniture with automatic labeling, feeding, carving, cutting, drilling, grooving, and discharge.

Product Descriptions

Advantages of Full Automatic CNC router for Furniture Making:

1. Increase 10% material usage.

2. Reduce the dependence of the technical workers.

3. Decrease of sorting procedure and sorting error.

4. Save both time and labour for complicated workpiece processing.

5. It can also groove and drill.

6. Improve the product quality and the efficiency.

7. Optimize technology procedure, reduce the production cost.

Applications of Full Automatic CNC Router for Furniture Making:

1. Furniture industries

Cabinet doors, wooden doors, solid woods, plates, antique furniture, doors, windows, tables and chairs.

2. Decoration industries

Screens, wave boards, large-size wall hangings, advertising boards and sign making.

3. Arts & Crafts industries

Achieveing effects of exquisite patterns and characters on artificial stones, woods, bamboos, marbles, organic boards, double-color boards and so on.

4. Processing material

Carving, milling and cutting for acrylic, PVC, density boards, artificial stones, organic glass, plastics and soft metal sheets such as copper and aluminum.

Features of Full Automatic CNC Router for Furniture Making:

Full automatic CNC router is mainly designed for customized furniture plans, such as kitchen cabinet and wardrobe, the whole production line only need one ordinary worker to operate.

The CNC router machine can mix a lot of your customers orders from a BOM automiticallythough the software:

1. Automatic Labeling

The machine can show a barcode / order No. / board size information on each board. The label information can be customized according to your requirements.

2. Automatic Feeding

Suck the board to the next process automatically.

3. Automatic CNC Machining

Cutting, milling, drilling and engraving automatically.

4. Automatic Discharge

After process, the boards are discharged automatically.

Technical Parameters of Full Automatic CNC Router for Furniture Making:

| Model | APEX5 | |

| Working travel | X axis | 1300mm |

| Y axis | 2500mm | |

| C axis | 200mm | |

| Table structure | Vacuum suction | |

| orbit | HIWIN or PMI square orbit | |

| Transmission type | X, Y Rack, Z Ball Screw | |

| Repositioning accuracy | ||