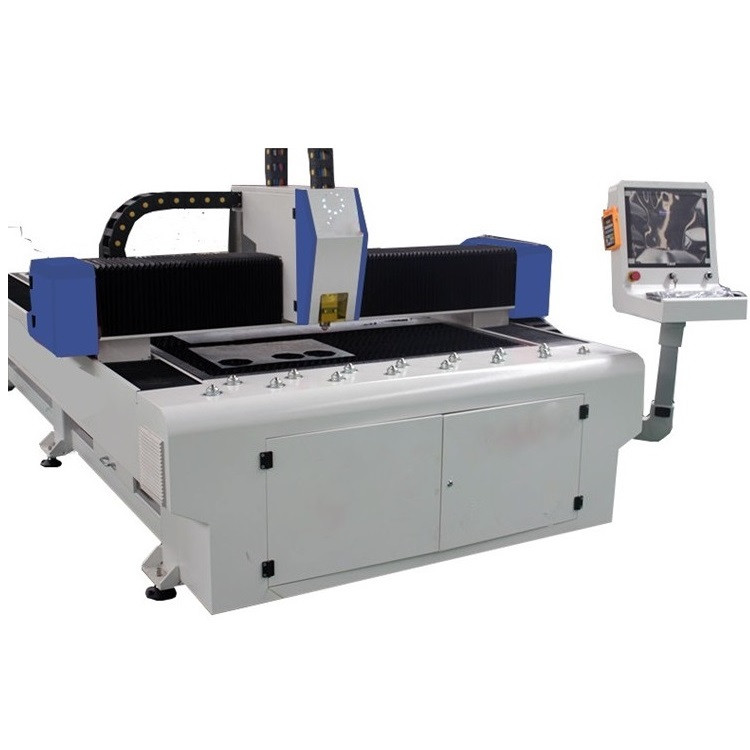

1530 Fiber Laser Cutting Machine for Sheet Metal Fabrication

APEX3015L is a heavy duty fiber laser cutting machine for sheet metal fabrication, you can choose different laser powers, such as 1000W, 1500W, 2000W and 3000W, the laser source can be Chinese Raycus, Germany Precitec or Germany IPG brand. More than 3000W laser power, we have more professional fiber laser metal cutters for choose.

Product Descriptions

Features and Advantages of Heavy Duty fiber laser cutting machine for Sheet Metal Fabrication:

1. High rigidity fiber laser cutting machine bed segmented welding, adopts exclusive annealing processing with high-temperature NC electric resistance furnace, ensure long-time stable working of the machine.

2. All the guide rails and screw holes are milled by our professional 5 axis gantry milling machine to keep the levelness. This quality engineering and workmanship result in smooth precision cutting.

3. Machine rack and rails installed based on the dial indicator, table frame based on the marble gradienter. This quality engineering and workmanship result in smooth precision cutting.

4. The gantry we adopted are new design aircraft-grade aluminum casting, replace of the welded steel gantry, more light-footed to make the whole machine working very fast.

5. New machine body whole frame with smoke extraction,reduce the smoke and chippings to harm the cutting head and lens.

6. Taiwan Hiwin square rails:

Each parts we adopted are original, such as Taiwan Hiwin rails with flange, high accuracy, Zero-distance to avoid the dust accumulation.

7. Swiss Raytool fiber laser cutting head, more closure to protect the parts inside.

From 1500W, we will free upgrade to laser cutting head with auto focus.

8. Different brand laser source for choose:

Technical Parameters of Heavy Duty Fiber Laser Cutting Machine for Sheet Metal Fabrication:

| Model | APEX3015L |

| Working Area | 1500mm*3000mm |

| Max Cutting Speed | 80m/min |

| Laser Power | 1000W/1500W/2000W/3000W |

| Max Acceleration | 1G |

| Repeated Positioning Accuracy | 0.02mm |

| Driving Way | Yaskawa Servo motor |

| Transmission Way | Y-axis gear rack double driver, X-axis ball screw |

| Power Requirements | 380V/50HZ/3P (220V Avaliable) |

| Machine Weight | 3500kg |

Applications of Heavy Duty Fiber Laser Cutting Machine for Sheet Metal Fabrication:

APEX3015L fiber laser cutting machine is widely used in electrical power, automobile manufacturing, machinery and equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising signs, car decoration, sheet metal production, lighting hardware, display equipment, precision components, metal products and other industries.

Specialized fast speed cutting of a variety of metal plates, pipes(add pipe cutting device), mainly used in stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass, aluminum, steel, various alloy plate, rare metal and other materials.

Heavy Duty Fiber Laser Cutting Machine for Sheet Metal Fabrication In Factory:

Package of Heavy Duty Fiber Laser Cutting Machine for Sheet Metal Fabrication:

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard protective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Heavy Duty Fiber Laser Cutting Machine for Sheet Metal Fabrication Projects:

International Shipping Around the World

All the CNC laser machines can be shipped worldwide by sea, by air or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.