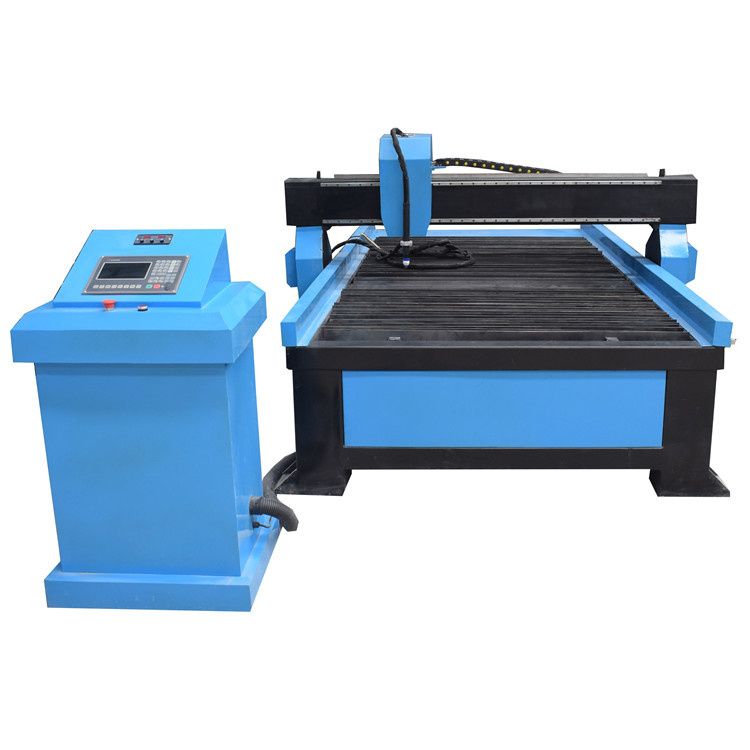

Industrial CNC Plasma Table with Flame Cutting Torch for Hot sales 2021

4×8 industrial CNC plasma table with flame cutting torch is a commercial plasma table used for sheet metals and metal tubes, if the metal thickness is less than 10mm, you should cut with plasma torch, if the metal thickness is more than 10mm, you should cut with flame torch.

Product Descriptions

Advantages and Benefits of Industrial CNC plasma table with Flame Cutting Torch

1. Welded lathe bed of thick profiled steel, which is more solid and stable.

2. Perfect lathe table design, 10mm steel plates fixed on lathe table covered by cast iron. The level difference of platform remains in 0-1.5mm.

3. Advanced material inclined discharging design.

4. Top CNC system configuration, automatic arc, stable performance, the success rate of 99% arc.

5. The CNC plasma table supports Fastcam, ARTCAM, Type3 software, which is easy to operate.

6. Plasma torch power supply supports all top brands.

7. The rotary device can be used for cutting round metal tube, the square tube cutting rotary is optional.

Applications of Industrial CNC Plasma Table with Flame Cutting Torch

Applicable materials

Iron plate and pipe, Aluminum sheet and tube, Galvanized sheet and pipe, Stainless steel sheet and tube, Titanium plate and pipe, etc.

Applicable industries

Case shell of mechanical and electrical products processing, advertising signages, process decoration, black smith gardens, automobile, shipbuilding, electrical accessories cutting and processing, welding industry, etc.

Technicial Parameters of Industrial CNC Plasma Table with Flame Cutting Torch

| Description | APEX1325R |

| Working Size | 1300*2500mm |

| Rotary dimension | 200-500mm diameter, 3000mm-6000mm length |

| Table Type | Sawtooth or water tray |

| Transmission System | Gear rack transmission and Hiwin guide rails |

| Driving System | Stepper motor and drivers |

| Max. Cutting Speed | 12000mm/min |

| Max. Travelling Speed | 20000mm/min |

| Working Voltage | 220V/2P for machine, 380V/3P for power supply |

| Arc Mode | Untouched arc striking |

| Output Current | 63A, 100A, 120A, 160A, 200A |

| Command | G code, *uoo, *mmg, *plt |

| Operating System | Starfire Controller |

| Consumable parts | Electrode and nozzle |

Features of Industrial CNC Plasma Table with Flame Cutting Torch

1. Gantry structure, perfect bearing capability. The plasma machine body is strong, rigid, high precision, reliable and durable.

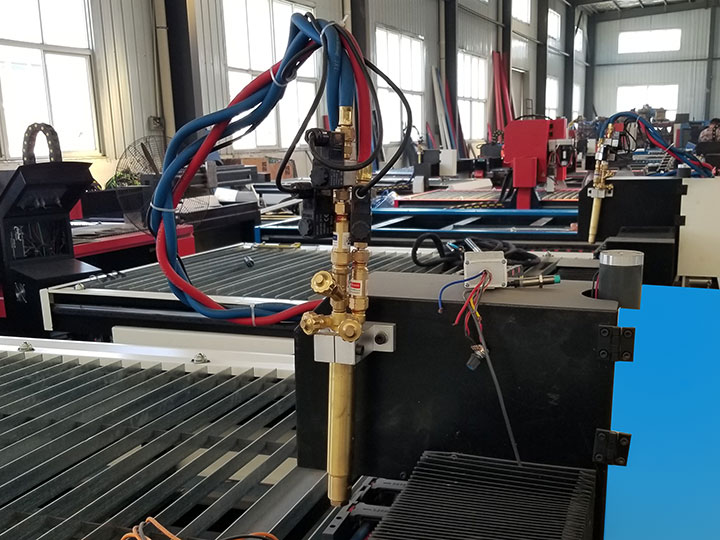

2. Double cutting torch:plasma cutting torch and flame cutting torch (Oxygen), it is suitable for cutting sheet metal of different thickness.

3. The CNC plasma cutter adopts well known plasma power, such as China Huayuan brand or America Hypertherm brand.

4. The plasma cutting edge is small and smooth, without drop outs, thickness for metal cutting is up to 50mm.

5. ARC voltage auto height-adjusting device, arcing success rate over 99%, which will protect cutting torch from damage, improve the cutting quality.

6. The commercial plasma table adopts high-precision Hiwin linear guide rails, smooth movement to ensure that the plasma machine tools with high-precision.

7. Drive gear and rack, customized from professional manufacturer, it is surface processed by cemented quenching, which can prolong machine

We are manufacturer of CNC router machines,which have widely application of many materials like wood, acrylics, stone, metal, plywood etc, with professional manufacturing process, and rich experience engineers for R&D, manufacturing, sales, and after sales service. Thus we can do both OEM and ODM service well, and client site machine installation, and technique support is available too. Now we are looking for agents and distributors worldwidely, welcome to visit or talk on line about mutual cooperations. Please talk with our international marketing manager about the cooperation, Mary Jane, whatsapp/cell phone: +(86) 15169183960.