Multifunctional Handheld Fiber Laser Welding Machine easy to use

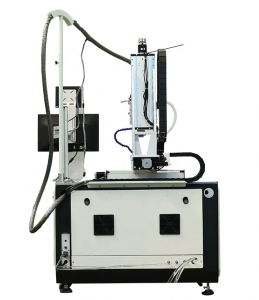

Main Parts of the Handheld Laser Welder

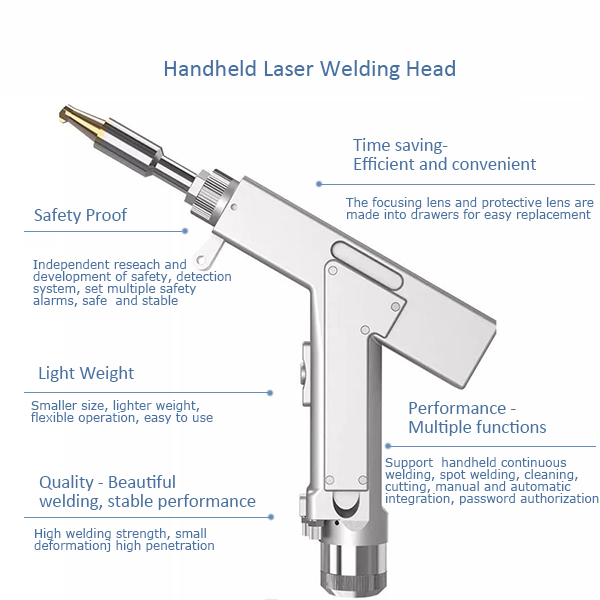

1. Advantage of the leaser head

2. System/Wire Feeder (Super Albert Control System)

>>>Easy installation, long life, low noise and low energy consumption

>>>Small size, light weight, large torque, can be used with long-distance hand-held welding wire feeding

>>>The wire feeding is synchronized with the welding control, and the wire feeding is stable and adjustable.

>>>Software control, the wire feeding speed parameters are designed through the control screen, and multiple sets of data can be saved and called arbitrarily.

3. Raycus Laser

High photoelectric conversion efficiency

Maintenance-free operation

Efficient thin plate cutting

Output fiber length can be customized

Modulation frequency range

Anti-high anti-reaction ability

QBH connector

4. S & A Water Chiller

>>>The temperature control accuracy can reach ±0.5C

>>>Environmentally friendly refrigerants can be selected

>>>Dual temperature and dual control modes to meet the different cooling needs of fiber lasers and welding heads

>>>With a variety of alarm protection functions: compressor delay protection; compressor overcurrent protection; water flow alarm; high temperature / low temperature alarm

>>>Stable refrigeration and easy operation

>>>Optional heater and water purification configuration.

Parameters of the Handheld Laser Welder

| APEX-HWA2 Parameters | ||

| Power | 1000W | 1500W |

| Weld thickness | 0.3mm-3mm | 0.3mm-4.5mm |

| Electricity Demand | 220V±10V | 220V±10V |

| Machine Size | Length: 98cm Width: 60cm Height: 115cm |

|

| Machine Net Weight and Wire Feeder | 200KG | 210KG |

| Machine Gross Weight | 255KG | 265KG |

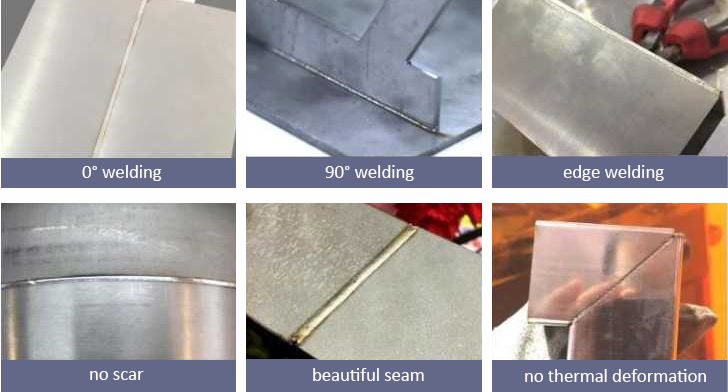

Customers Samples Photos

Laser welding is a method of using a high-energy density laser beam as a heat source to locally heat the material in a small area, and melt the material to form a specific molten pool to achieve the effect of welding

Laser welding is mainly used in the welding of thin-walled materials, precision parts, etc. It can realize spot welding, splicing welding, sealing welding, stitch welding, etc., with small thermal deformation, beautiful and smooth weld seam, high quality weld seam, no need for secondary grinding deal with.

APPLICATIONS:

It is widely used in sheet metal processing, cabinet kitchenware, chassis cabinets, stair handrails, elevator escalators, display shelves, Doors and windows, advertising models, stainless steel products and many other industries.

MATERIALS:

In recent years, laser welding has been widely used in the welding of stainless steel, carbon steel, galvanized sheet, copper, aluminum and other products.