When large stones need to be cut, a bridge saw is often used to cut them. For example, a large block of granite or marble is cut into small rock fragments that require a bridge saw to process into manageable stone slabs. Typically, bridge saws are several feet in size to accommodate large stones and similar materials. In this article, we will discuss the basic functions of bridge saws, their operation, classification, and the best bridge saw recommendations for stone cutting. Let’s learn about bridge saws.

What Is A Bridge Saw?

A bridge saw is used for stone cutting and as the name suggests, a bridge saw is a machine that resembles a bridge. It consists of a beam, two posts or brackets, passing through a bridge that spans several feet. The bridge is the track on which the saw head moves. The size of the stone slab that can be cut is limited by the width of this bridge.

Like all stone cutting saws, bridge saws are equipped with diamond blades to perform the stone cutting. A water pump system flows water through the stone and the saw blade during the cutting process to keep the blade cool and reduce dust emissions in the air.When using a bridge saw for stone cutting, the cutting head and saw blade simultaneously pass through the bridge while passing through granite, marble and other materials.

How to Operate A Bridge Saw?

The first step in cutting stone with a bridge saw is to set up and check the machine correctly. First, make sure the diamond blade is suitable for any type of stone to be cut, that it is the right size for the bridge saw, and that it is installed correctly. The water pump and any other power cords, cables, or belts should also be checked to ensure they are compatible with the machine. If applicable, check the oil level and gasoline level of the motor. The operator of the bridge saw should also wear the correct personal protective equipment and make sure there are no other people around to ensure the safety of other people.

When cutting, the stone should be placed on the table under the bridge saw. The saw blade should be aligned with the mark on the stone to be cut. First, turn on the water pump and carefully check that water is flowing freely over the saw blade. Then, you can turn on the saw blade.

The operating procedures will vary slightly from manufacturer to manufacturer and you will need to consult the user manual. Generally, the machine is usually operated in a semi-automatic program. The operator sets the parameters through the control panel, and the cutting head moves down into the stone and across the bridge, cutting all the way to the other end. You can set the height of the cutting head during the cutting process to control the cutting depth.

Five-axis Bridge Saw:

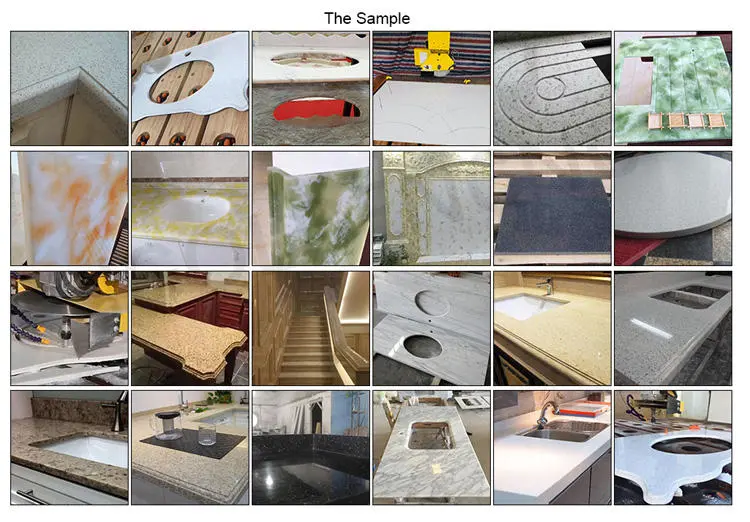

The main processing function of ordinary bridge cutting machines is stone slab cutting. For the overall countertop processing, there are many processes, and cutting plates is only one of the functions. Ordinary stone bridge cutting machines cannot complete special-shaped cutting, 45° trimming, drilling, polishing and grinding.

Using a five-axis bridge cutting machine, the above processing steps can be completed in one go without secondary processing, saving manpower, reducing power consumption, and high efficiency, which can greatly improve the efficiency of the enterprise. The functions of the five-axis bridge cutting machine include accurate positioning, guaranteed completion of the process, accuracy, and speed; special-shaped trimming can be performed to achieve sawing and grinding of various angles.

With an automatic tool change spindle, engraving can be completed simultaneously, and the saw blade, milling cutter, forming wheel and polishing wheel can be switched automatically. Cutting, chamfering, and polishing functions can all be realized without repeated positioning, improving processing accuracy, processing quality, and processing efficiency.

Features of Five-axis Bridge Saw:

This 5-axis bridge cutting machine integrates cutting, milling, drilling and polishing, and can realize cutting of granite slabs, quartz faceting, marble rough material, etc. It is mainly used for tombstone manufacturing, cabinet countertop processing, bathtub processing, etc. This machine has the following features:

1. It has a complete stone processing line, realizing automatic loading, automatic unloading, automatic typesetting, automatic tool setting, automatic unloading, etc.

2. This CNC granite bridge cutting machine cutting line can be used for cutting marble, granite, jade, bluestone, etc., and is widely used in hotels, construction, etc.

3. This 5-axis bridge cutting machine can realize X-Y-Z-A-C five-axis linkage processing, rotate 0-365°, tilt 90°, and realize cutting in any direction and at any angle.

4. The equipped granite saw blade can complete the cutting, chamfering, polishing, grooving, drilling, arc grinding, etc. of granite stone.

Conclusion:

Bridge saw is an important tool for stone cutting. The processing of various plates in life depends on bridge saw. When choosing a bridge saw, you need to choose according to your actual needs. If you only want to perform simple plate cutting and do not need to cut complex shapes such as patterns, it is recommended that you choose a three-axis bridge saw. If the shape to be cut is more complex, you can choose a 4-axis bridge saw. If the processed shape needs to be cut in any direction and at any angle, it is recommended that you choose a 5-axis bridge saw. At the same time, as the number of axes increases, the price of the bridge saw will become higher and higher. It does not mean that the more expensive the machine, the better. You still have to choose according to the actual needs of the processing.

Post time: Jan-23-2025