Since its birth, the sheet metal laser cutting machine has been a hot spot in the society, because it is widely used, from the simplest sheet metal processing, to billboard cutting, metal lighting, kitchenware and bathroom industries, and laser cutting is indispensable. Did you know that the metal parts and electrical cabinets of the household appliances we use every day are all laser-cut.

In electrical products, the parts processed from sheet metal almost account for more than 30% of all product parts. The traditional blanking, corner cutting, opening and trimming processes are relatively backward, which directly affects product quality and production costs.

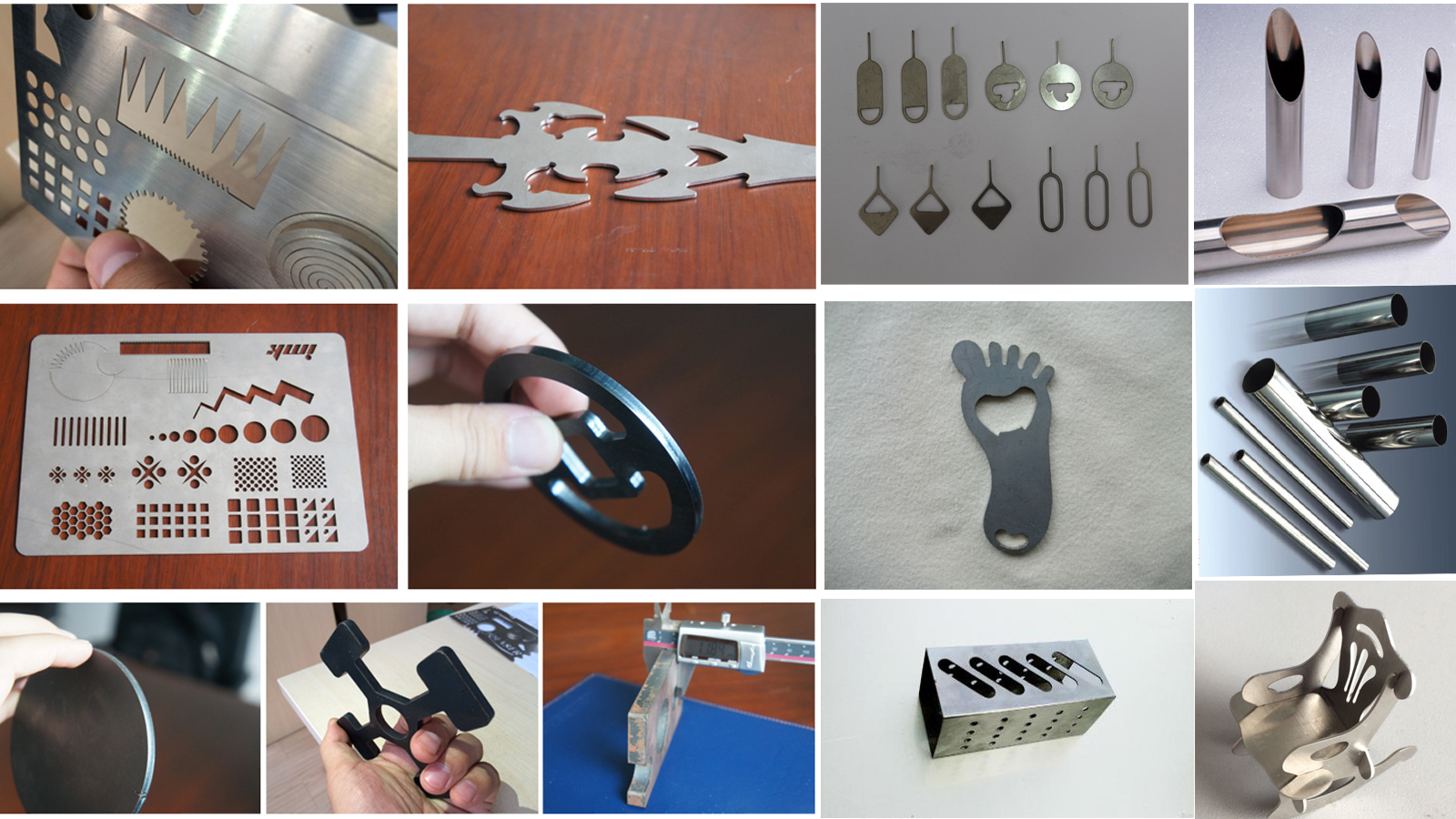

Among the commonly used electrical products, the thin plate laser cutting machine is mainly used in the shell metal parts of washing machines, refrigerators, air conditioners and other products, and the drilling and cutting of metal parts. For example, thin steel plate parts can be cut, metal parts of air conditioners, metal casings can be cut, the bottom or back cooling screen of refrigerators can be cut and punched, and the metal smoke guide plates of range hoods can be cut. There are also some small appliances, such as juicer blade cutting, microwave cutting, microwave technology cooling plate cutting, and laser cutting can also be used.

The laser cutting machine has the incomparable flexibility and processing accuracy of traditional processing methods. Because it adopts “contactless processing”, it does not require mold making and cost. The processing graphics are made by software and have various patterns. Therefore, laser cutting technology can effectively improve product quality, reduce production costs, reduce labor intensity, improve traditional sheet metal processing technology, and bring better production benefits to manufacturers.

With the intelligent development of the home appliance industry, in the manufacturing process of electrical appliances, the requirements for sheet metal parts and parts are becoming more and more refined, and the shapes are complex and the process is more difficult. The laser cutting technology can effectively meet the above needs. From the perspective of industrial development, the in-depth application of laser cutting in the home appliance industry will become a trend.

The traditional processing technology of the home appliance industry is constantly being transformed and upgraded. Whether laser cutting improves the processing quality or optimizes the appearance of the product, the competitiveness is gradually concave, and its importance has been gradually recognized by manufacturers, and its application in the home appliance industry will become more and more. The more extensive, its development potential and market opportunities will be immeasurable.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Jun-10-2022