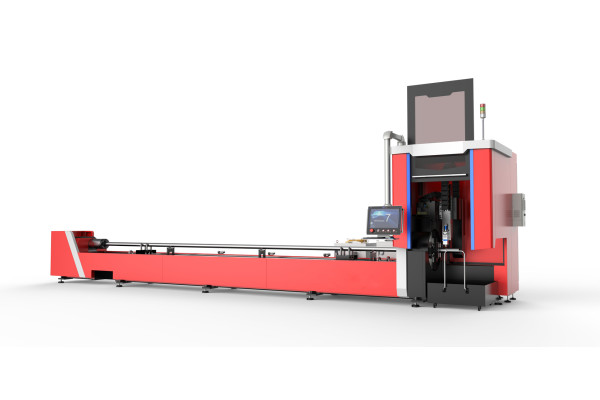

New APEX2060 professional fiber tube laser cutting machine has high performance and fast response, but what advantages does it have? please check below:

1.Chuck clamping design

The front and rear dual pneumatic chucks are used for clamping design, and the rear chuck is equipped with a blowing device to reduce the slag attached to the pipe wall during cutting.The clamping force can be adjusted arbitrarily, and different strengths can bear different loads to avoid the deformation of the thin pipe clamp and the looseness of the thick pipe clamp.The chuck is 200 mm and has a wide clamping range. It is suitable for various pipes and can be automatically adjusted according to different pipe diameters and thicknesses. The rotating speed of the chuck is high, the speed can reach 70 revolutions per minute, and the feeding speed can reach 90 meters per minute, which effectively improves the processing efficiency.

2. Automatic support device

Intelligent pipe cutting design, pneumatic support, bearing weight of 1.2 tons, helical gear transmission effectively reduces the noise and vibration caused by gear engagement during chuck transmission, and ensures the stability of cutting. The support is equipped with variable diameter wheels, which can be suitable for supporting pipes of different diameters.

3. Plate welding bed

The whole bed is welded with 12 mm steel plate, and it will not be deformed after 30 years of use. The bed weight is 5.5 tons, the load-bearing weight is 1.2 tons, and the whole machine weighs up to 9 tons. It runs stably during the processing process and guarantees cutting accuracy.

4. Professional cutting head for pipe

Equipped with a three-dimensional cutting head, the cutting efficiency is higher, the performance is better, the cutting effect is better, the obstacle avoidance function is stronger, and it is light and smart, and it can easily control many types of pipes.

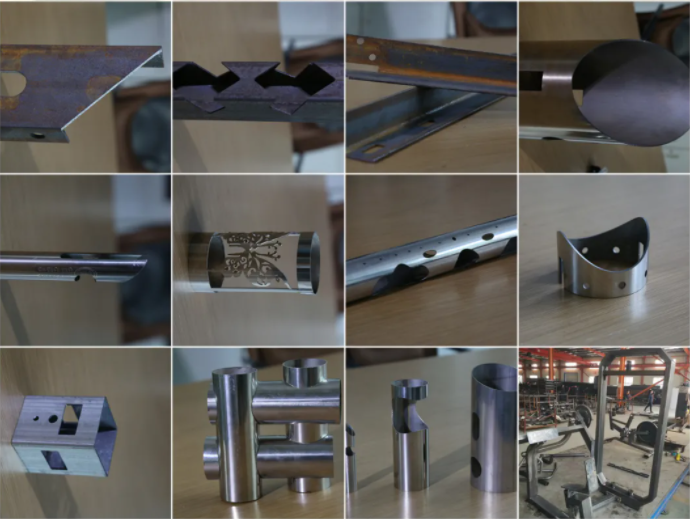

The range of pipes processed by this equipment can reach up to 7.5 meters, the rear chuck can also be extended into the front chuck, and the cutting tail can be controlled within 100 mm! Less tails, the production cost savings for businesses.

In addition, the intelligent software system is also equipped with various black technologies such as automatic centering, flying cutting, one-click tube head alignment, four-sided centering, etc. It can also be equipped with nesting software, and automatic or semi-automatic loading and unloading systems.

Post time: Aug-24-2021