The cabinet consists of five major parts, cabinet body, cabinet doors, cabinet hardware, countertops, and electrical appliances. With the popularity and demand expansion of cabinet production, a whole cabinet customization boom has been set off. More and more customers need cabinet customization services. So how to get a suitable cabinet solution? Below, I will provide you with the best two cabinet solutions to make money.

Cabinet Door Production Process

1. There are many kinds of materials and colors for the cabinet door panels. And they are usually produced according to custom cabinet orders. The equipment mainly includes CNC panel saws and manual sliding table saws.

2. The purpose of cabinet door slotting is to install the aluminum buckle handle.

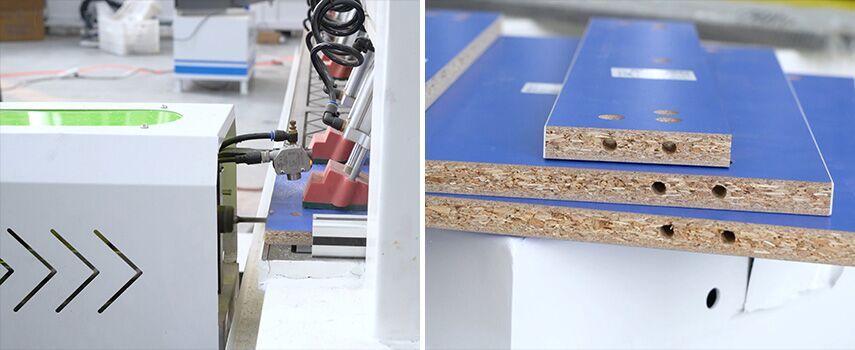

3.Generally, the materials to be banded are melamine, fireproof board, crystal board, etc. The edge to be banded is generally the same color as the door panel with 2mm thickness. Also, in order to improve the quality, it adopts aluminum edge banding. And the equipment is mainly an automatic edge banding machine.

4.

5.The drilling hole here is a door hinge hole. In order to reduce the error rate, it often leaves to the dealer.

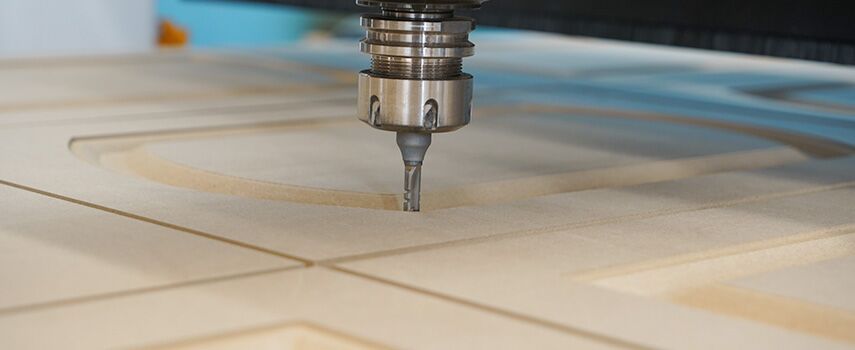

6.Gong grooving is for making cabinet door patterns. The processing equipment is mainly ATC CNC machine.

7.The steps of blistering are very simple. First, polish the cabinet door. Then spray glue and put the door panel into the blister machine. Last, carry out the blistering machine- vacuum pressing machine to process.

8.The process of baking paint is quite complicated and it is mainly made by hand. So, if you want to spray high-quality cabinet doors, you must have more experience and technology.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Feb-28-2023