As a combination of drilling and milling, CNC engraving machine is mainly used for engraving with a certain depth mark on the surface of objects. Relying on the advantages of complete types, complete functions, high processing accuracy, and high processing efficiency, the CNC router is widely used by domestic and foreign users in various industries such as advertising industry, technology industry, mold industry, electronics industry, construction industry, printing and packaging industry, decoration industry, tombstone industry, crystal products industry. The following are the main applications of engraving machines in various industries.

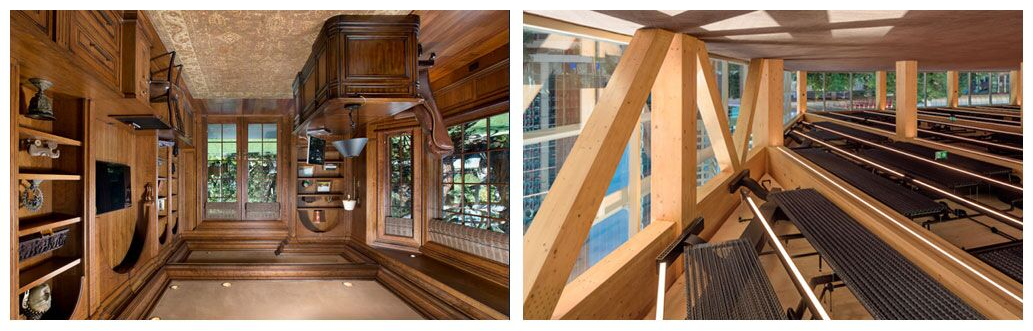

1. Furniture industry

CNC engraving machine produces engraving parts, with high production speed and high precision. With the characteristics of complete types, high intelligence, practicality and efficiency, mass production, high speed and high efficiency, it can realize most solid wood engraving or panel milling operations. And it can retain the natural color, texture and texture of solid wood materials, so it is widely used in the furniture industry and has become the first choice for the furniture manufacturing industry. For example, the application of the engraving machine in the furniture industry is shown in the plane carving of large-area plates, solid wood furniture carving, solid wood art mural carving, solid wood carving, MDF paint-free door carving, kitchen window door carving.

2. Wood products industry

Wood products mainly cover furniture wood products, office wood products, craft wood products, garden wood products, living wood products and other major fields. The processing of the engraving machine covers no matter what field it is, the engraving machine can easily achieve the ideal processing effect. In addition, the engraving machine can also be displayed in the production of wooden industrial products such as sewing machine countertop, electrical cabinet panels, sports equipment and so on.

3. Advertising industry

Common materials in the advertising industry are non-metallic materials such as double-color boards, organic boards (acrylic), artificial stones, PVC boards, wood, MDF, and ABS. The advertising industry mainly involves badges, modeling, steel molds, carved seals, furniture carvings, gifts, souvenirs, handicrafts, signboards, sign production, hand boards, punching, printing factory knife molds, advertising word cutting, carving advertising light box production, etc. . The engraving machine has simple operation, flexible processing methods, and excellent processing quality. It has always been popular among users in the advertising industry.

4. Mold industry

In the process of mold manufacturing and production, the use of CNC machining technology can not only ensure the accuracy of the mold, but also facilitate the efficient and efficient design and processing of the mold. Therefore, CNC technology plays an important role in mold manufacturing. In the mold industry, CNC engraving machines can be used to engrave various architectural models, physical models, bronzing molds, motors, wooden molds, aviation wooden molds, propellers, automobile foam molds, shoe molds, badges, embossing molds, cookies, chocolates, and candy Mold etc.

5.Residential and construction industry

Residential / commercial construction: Residential / Commercial Construction: cnc router can be applied to all kinds of wooden decoration, such as stairs, railings, panels and slat fences can be durable for many years, private houses often use wooden frame, wooden floor, and wooden structure stairs. Large wooden beams, wooden window frames, wooden floors, paneling and cabinets can often create breathtaking commercial spaces. Modular wooden buildings can be assembled in an instant to produce large and complex wooden structures such as factories and warehouses. These blue elephant wood carving machines can do it for you.

6. Stone carving industry

The CNC engraving machine is a product of the combination of traditional engraving technology and modern CNC technology. It inherits the fine, light and flexible operation characteristics of traditional engraving. At the same time, it uses the automation technology in modern CNC machining and is widely used in various industries. The processing materials mainly involved in the stone carving industry include granite, marble, artificial stone, bluestone, sandstone and other various stones. The stone carving industry mainly involves small-sized stone products for viewing and hanging. As well as figures and animal stone carvings. Such as celebrity statues, Buddha statues, stone lions, etc. There are also some daily necessities including tables, chairs, stools, coffee tables, lamps, inkwells, etc. There are also some inscriptions and stone carvings. Such as various monuments, tombstones, etc.

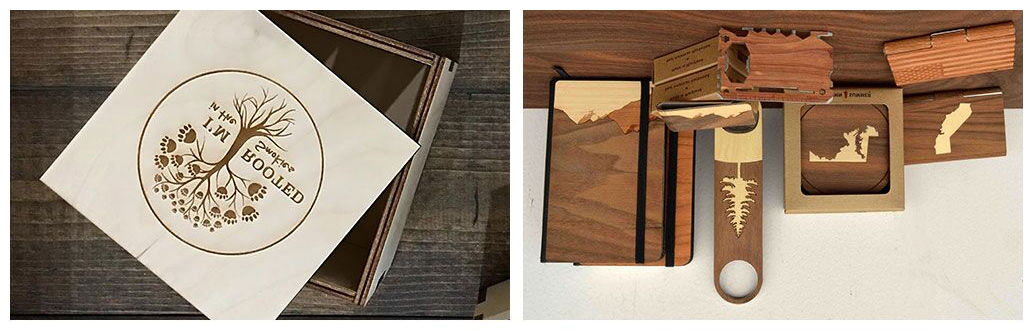

7.Crafts industry

The crafts industry mainly involves various furniture, lighting, ornaments, models, root carvings, study, utensils, pen holders, combs, screens, doors, coat racks, coffee tables, craft boxes, jewelry boxes, jewelry boxes, wine racks, craft painting , Buddha statues, pendants, etc. Engraving machines in the handicraft industry are characterized by carving various types of characters, patterns, and outlines on various handicrafts and souvenirs.

8. Musical instrument industry

Many musical instruments are mainly made of wooden materials, including clarinet, oboe, big pipe, clarinet, special flute, flute, Sheng and other woodwind instruments, Huqin, matouqin, violin, Banhu, Yehu and other bowed string instruments, clapper, wooden fish, sound Percussion instruments such as boards and drums. The application of the engraving machine in the musical instrument industry is manifested in engraving the three-dimensional curved surface of the musical instrument and cutting the appearance.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Dec-15-2022