Machine advantage

1. instead of manual cutting, efficiency increase 4-6 times , Savings of 4-6 labor costs

2. environmental protection smoke-free, product consumables are very few

3. effectively solves the problem that hard cloth can not be cut manually

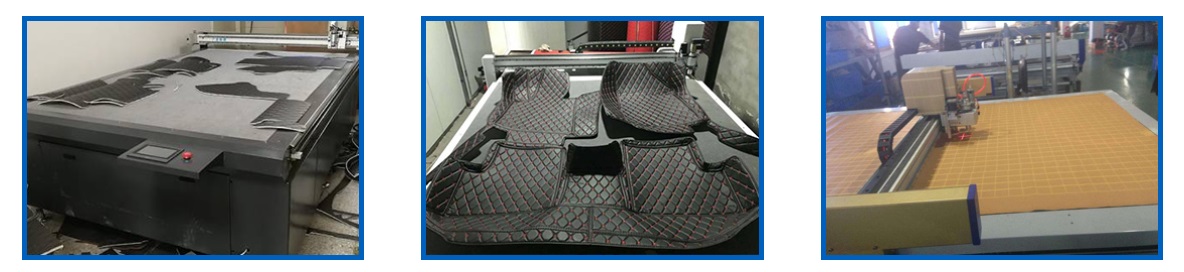

Machine Applications:

car seat cushions ,fur cutting ,carpet floor pads ,sofa seat covers, luggage shoes,

large format cutting,leather industry,clothing proofing, packaging printing, handicraft gifts

Our focus:

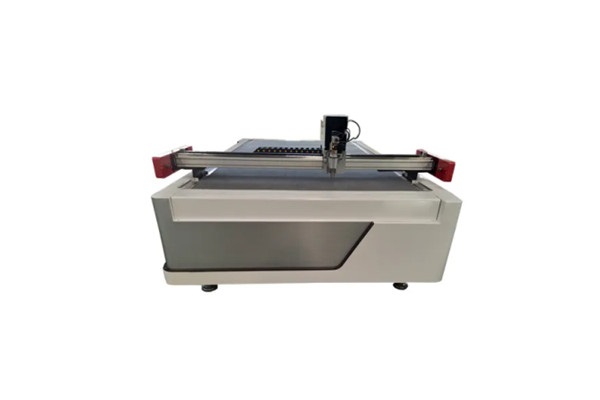

Compatible material vibration knife cutting machine:

1, tungsten steel blade, can cut high-strength materials

2. Precise cutting, the error is ±0.02mm, the blade is smokeless and tasteless, environmentally friendly

Fur vibration knife cutting machine:

1. Save more than 10% of materials, cut efficiently, instead of 4-6 labor

2. It does not hurt the plush shears program to ensure beautiful cutting

Leather luggage vibration knife cutting machine

1. Suitable for cutting imitation leather, artificial leather and part of genuine leather

2. It has the characteristics of smoke-free, dust-free, high efficiency and material saving

Car mat vibration knife cutting machine:

1. Suitable for PVC carpets, printed carpets, long-haired carpets and other carpet materials

2. It has the advantages of smooth cutting, no hair damage, and high efficiency

Sofa home textile vibration knife cutting machine:

1. Vacuum adsorption table, automatic tiling of materials, no need for labor

2. Personalized customization, data import one-click cutting

Carpet vibrating knife cutting machine:

1. Suitable for PVC carpets, printed carpets, long-haired carpets and other carpet materials

2. It has the advantages of smooth cutting, no hair damage, and high efficiency

Rotary knife vibrating knife cutting machine:

1. No need to make knife molds, saving development time

2. It can complete difficult and complex pattern cutting

Garment fabric cutting machine:

1. 2000mm/s efficient cutting, 4-6 times manual speed

2. Software intelligent compensation, cut

Why choose us?

1.Applicable industries: garment proofing, carpet floor mats, sofa seat covers, luggage shoes, large format cutting, leather industry, shoe industry packaging and printing industry, etc.

2. 10000 flat production base

15 per cent savings in procurement costs

The production line is sufficient, the production cycle is short, the delivery is fast, and the production and use are not delayed.

3. New upgrade core accessories have higher quality accuracy and improve performance-to-price ratio

Using precision guideway + rack drive to ensure adsorption stability

Standard imported transmission felt

4. Provide door-to-door installation, training, after-sales service, lifelong free upgrade software

5. Professional after-sale

Ultra-long quality assurance for 12 months, lifelong after-sale

Provincial chauffeur, provincial logistics direct. Can be delivered in an average of 2 to 5 days

Post time: Jul-08-2021