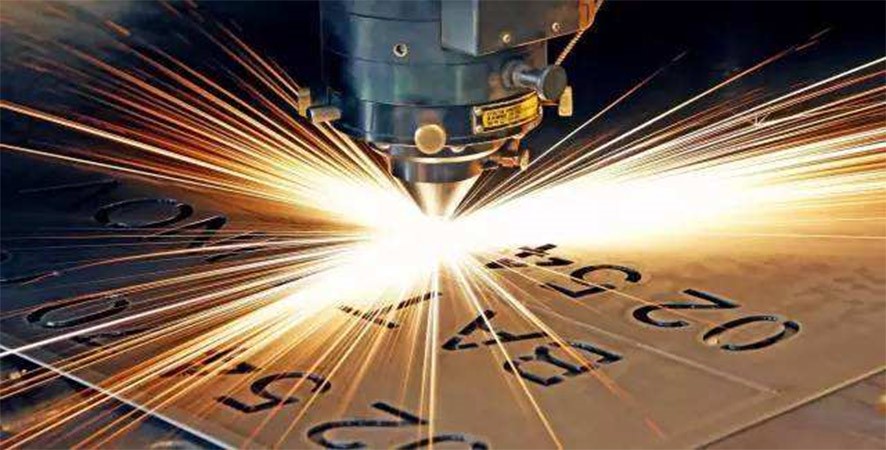

With the recovery of the global economy and the rapid development of laser technology, laser cutting systems have been widely used in key industries such as aerospace, rail transit, automobile manufacturing, and sheet metal fabrication. The advent of fiber laser cutting machine is undoubtedly an epoch-making milestone in the entire history of laser cutting.

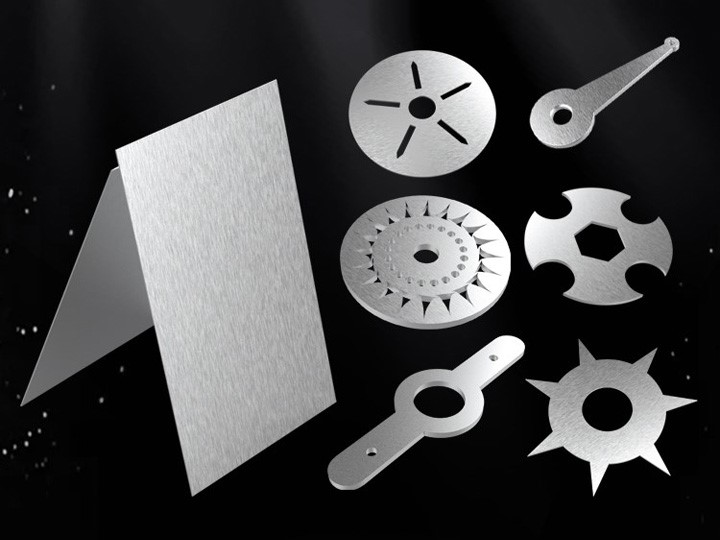

Shearing, punching and bending are traditional methods of sheet metal fabrication. During the processing, these methods cannot be separated from the mold, and hundreds of molds are often assembled during the processing. The widespread use of molds not only increases the time cost and capital cost of the product, but also reduces the accuracy of product processing, affects the repeatability of the product, and is not conducive to changes in the production process. This is not conducive to improving production efficiency. The use of laser machining technology can save a large number of molds in the production process, shorten production time, reduce production costs, and improve product accuracy. Laser cutting of stamping parts can also ensure the accuracy of mold design. Blanking is the previous painting process, and its size is usually modified. The size of the blanking die can be determined more accurately through the trial production of laser cutting and blanking parts, which has become the basis for mass production of sheet metal fabrication.

It is precisely because fiber laser cutters have many unique advantages that will accelerate their expansion in the global laser cutting market. Since 1980, the global installation of thin-sheet laser cutting systems using high-power CO2 lasers as light sources has been roughly 50,000 units; the annual sales volume has been roughly 3500-4000 units. Therefore, the market penetration of high-power fiber lasers will set off a frenzy in the field of system supply. First, fiber lasers are likely to grab market share from CO2 laser suppliers. In the eyes of high-power CO2 laser suppliers, fiber lasers are gradually becoming a growing and highly competitive opponent. Second, fiber lasers can expand the metal laser machine market by absorbing those new system integrators who have not yet shown interest in CO2 lasers. Third, today many global companies with system integration supply flatbed cutting machines. When they encounter new competition, most of the measures they take are to add laser machines to their marketing mix, these three elements are promoting the current changes in the laser cutting market.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Jul-06-2022