With the continuous improvement of living standards, people’s pursuit of quality of life is getting higher and higher.

The “light luxury style” in the home furnishing industry is very popular and favored by people. The embellishment of metal elements, incorporating modern cutting and hollowing techniques, injects a light and luxurious atmosphere into the space; brightly colored alloy materials, tough lines and soft leather, fashionable design meets people’s pursuit of artistic sense of furniture. Light luxury high-end furniture is especially sought after by the younger generation after the 80s and 90s.

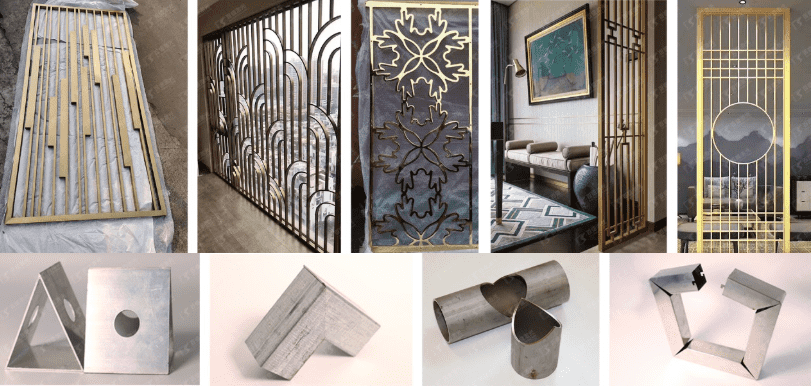

Many domestic furniture industry manufacturers are moving to incorporate more metal elements in product design. Such as metal lamps, metal edging of furniture, metal screens, metal decorative arts, etc.

High-end furniture is undoubtedly another market for the furniture industry. How to stand out in the fierce market competition?

The first thing to solve is the processing of furniture hardware. In order to meet the market’s pursuit of diversified and personalized furniture styles, metal furniture generally uses metal sheets and pipes. Traditional processing takes a long time, costs high, and it is difficult to guarantee accuracy. Many furniture industry manufacturers have begun to consider introducing laser cutting machines to cut materials. Compared with the traditional cutting method, laser cutting has the advantages of fast speed, good quality, high precision, safe and easy operation, etc. No matter how complicated the pattern is, you only need to draw the artwork on the computer and you can cut it. Greatly reduces labor costs and significantly improves production efficiency.

The following are the workpieces produced by a furniture industry manufacturer using a laser cutting machine:

The professional laser pipe cutting machine launched by Jinan APEX can cut stainless steel, carbon steel and other metal round pipes, square pipes, rectangular pipes, channel steel, I-beam, angle iron and special-shaped pipes. Zero-second perforation, storm cutting, fly-through symmetrical penetration, precise and efficient. To meet the diversified pipe cutting needs of the furniture industry, it has many good reputations in the furniture industry! Support the configuration of automatic loading and unloading racks, which can realize one-person control and mass production.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: May-26-2022