APEX engraving machine has many uses. The following summarizes 9 application areas of engraving machine.

1. Seal industry: seal engraving of various fonts and materials. …

2. Model industry: With the development of real estate, the demand for building models continues to increase. The sales office’s sales model, square model, and architectural design plan display and display, the expansion of the vehicle model market, and some ship models and industrial models also have the meaning of commemoration and collection. Engraving machine has become the best assistant for making models. …

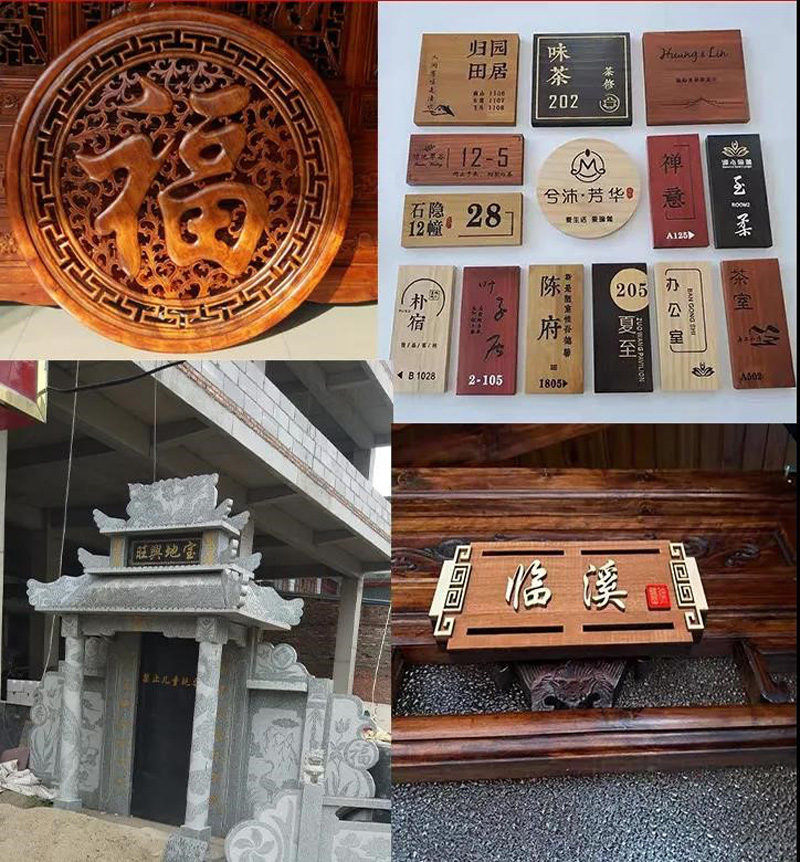

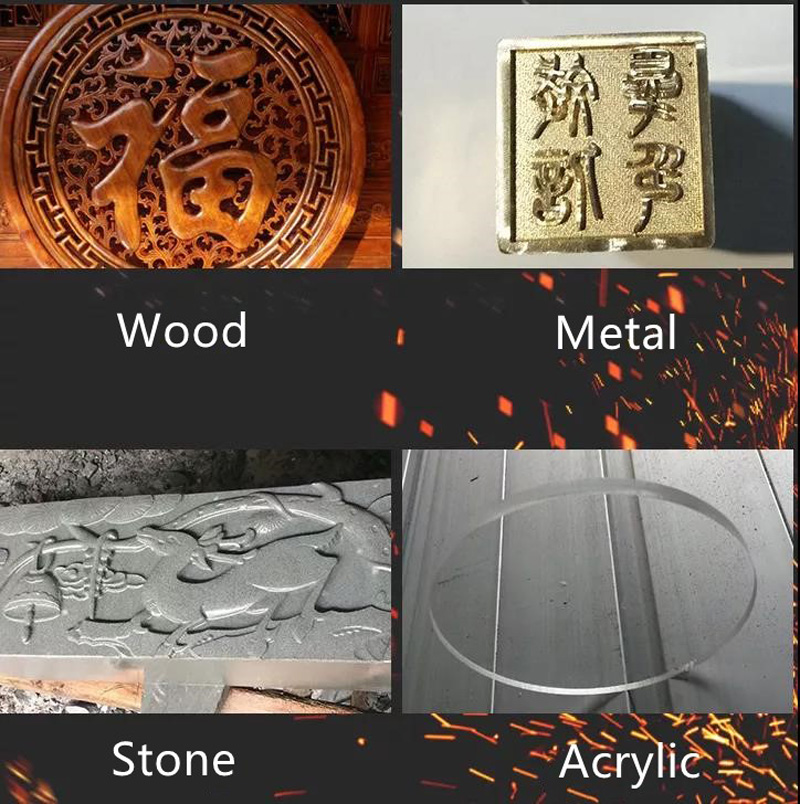

3. Wood craftsmanship: used for design and production of relief patterns. The engraving machine can be punched, pierced, etc., especially the wide application of new decorative materials and wave plates. It also gives the engraving machine more room for growth. While improving the repeatability and standardization of the product, it also improves the production efficiency of the finished product. Significantly improved. To

4. Mechanical processing industry: dial wheel and ruler scale. Moreover, with the continuous emergence of various new decorative materials, more and more materials can be used for carving, making computer engraving machines more useful. Therefore, the application range of engraving machines will continue to expand.

5. Advertisement and gift production industry: used to carve all kinds of two-color plate signs, plexiglass, three-dimensional billboards, two-color figure statues, embossed medals, organic plate embossments, three-dimensional door headers, etc. …

6. Automobile industry: tire mold, car lamp mold and jewelry mold processing. …

7. Printed circuit boards: circuit production, drilling, milling, etc. in the development of new products. …

8. Handicraft industry: With the continuous expansion of the tourism market, tourists have a soft spot for gifts with local customs, and engraving machines are also very useful in this regard. Moreover, there are more and more meetings nowadays. For some souvenirs and advertising materials, sculptures are popular. Engraving can be carried out on rings, key chains, trophies, imitation crystal ornaments, lighters, leather goods, watches, etc., which can reflect a person’s personality and taste. For some people with more ideas, it is also unique. For these Objects are carved with interest, which caters to people’s needs for emotional communication.

9. Sign industry: With the continuous development of our country’s economy, the ever-changing urban public infrastructure, the renovation of streets and roads, the continuous construction of modern residential quarters, star-rated hotels, and office buildings, have produced some signs and guidance systems that conform to trends and standards. There is a large amount of demand, among which plaque signs and signs made by engraving machines occupy a considerable part. The external signs have played a good role in the image of the company. It has become a trend to make badges, department cards, and floor cards worn by employees in the form of engraving.

Operation process of engraving machine

1. Typesetting according to APEX engraving machine customer requirements and design requirements, after the path is calculated correctly, save the paths of different tools and save them into different files.

2. After checking that the path is correct, open the path file in the engraving machine control system (preview available).

3. Fix the material and define the origin of the work. Turn on the spindle motor and adjust the number of revolutions correctly.

4. Turn on the power and operate the machine.

Turn on

(1) Turn on the power switch, the power indicator light is on, the machine first performs reset and self-check operation, X, Y, Z, axis return to the zero point, and then each run to the initial standby position (the initial origin of the machine).

(2) Use the handheld controller to adjust the X, Y, and Z axes respectively, and align them with the starting point (processing origin) of the engraving work. Properly select the rotation speed of the spindle and the feed speed to make the engraving machine in a working waiting state.

Engraving

(1) Edit the file to be engraved.

(2) Open the transfer file and transfer the file to the engraving machine to automatically complete the engraving work of the file. End When the engraving file ends, the engraving machine will automatically lift the knife and move to above the starting point of the work

Software operation process of APEX CNC engraving machine

(1) The engraving machine should be used correctly according to its technical performance requirements, and the engraving machine equipment that lacks or has failed safety devices shall not be used.

(2) Before and during engraving, check and confirm whether the cooling system (water pump) and lubrication system of the motor are working properly. To

(3) Pay attention to frequently clean up the debris in the motion box to ensure the normal operation of the machine tool.

(4) It is strictly forbidden to touch with your hands when the spindle is rotating to avoid accidental injury. To

(5) When clamping the workpiece, the principle of “installation, installation, and installation” must be followed, and it is strictly forbidden to engrave on suspended materials; in order to prevent material deformation, the thickness of the material should be greater than the engraving depth by more than 2mm. To

(6) The debris in the chuck head must be cleaned up before installing the tool on the APEX CNC engraving machine.

(7) When installing the APEX CNC engraving machine tool, you must first screw the chuck into the lock nut and place it upright, and install it on the motor shaft together, then insert the tool into the chuck, and then use the upper knife wrench to slowly lock Tighten the nut. When loading and unloading the tool, the loose nut is forbidden to push and pull, and the rotating method is used.

(8) The length of the tool exposed to the chuck must be determined jointly according to the engraving depth and whether the workpiece and the fixture interfere or not, and should be as short as possible when the above conditions are met.

(9) It is strictly forbidden to put any objects on the beams and baffles of the machine tool to avoid falling and hurting people. To

(10) The starting point of X, Y, Z axis must be defined correctly before machining. After changing the tool, you must immediately redefine the starting point of the Z axis, and the starting point of the X and Y axes cannot be changed. To

(11) When using the tool setting instrument to define the tool setting point, it is strictly forbidden to rotate the spindle to prevent damage to the tool setting instrument; it is strictly forbidden to fill the tool setting instrument with water or oil, and cover the tool setting instrument with a cup when not in use. To

(12) Before starting processing (cutting), place your hand on the red emergency switch button and press it immediately if there is an accident. To

(13) It is strictly forbidden to lie on the machine during operation, and it is not allowed to sit or lean on the machine frame. To

(14) It is strictly forbidden to hit the chuck with a wrench when unloading the knife. To

(15) Novice engravers must be diligent in hands-on and brainstorming during the operation of the machine. When using various engraving consumables, they must pay attention to economy and not waste.

(16) After processing, turn off the power of the machine tool, send the workpiece for inspection, clean up the tools and measuring tools, clean the machine tool and the ground, and fill in the “Instrument and Equipment Use Record” carefully.

Post time: Jan-05-2022