What is Laser Cleaning Machine and How Does it Work?

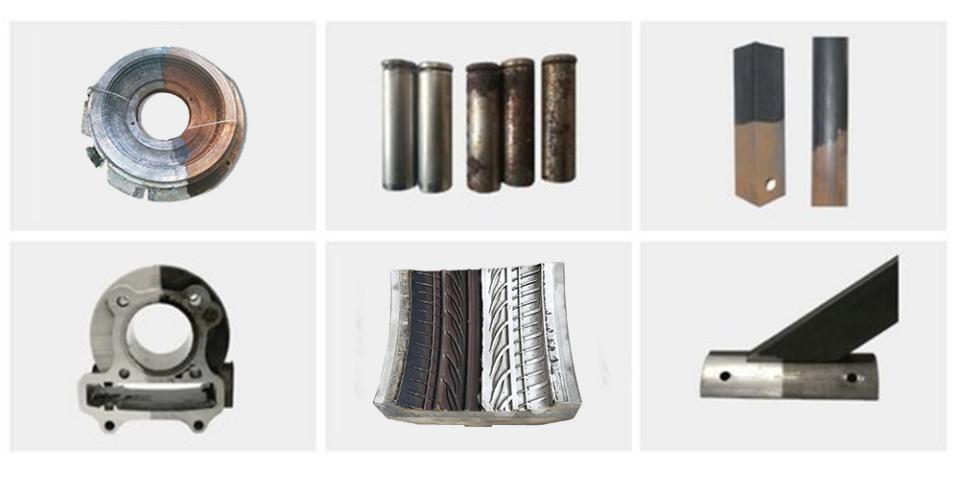

Laser cleaning is an environmentally friendly laser ablation or photoablation method to replace chemical and mechanical cleaning methods.Laser cleaning machine is a type of laser ablation machine to irradiate and heat the surface material of the object with a CW (Continuous Wave) laser or pulsed laser and make it evaporate or sublime to achieve the purpose of removing the surface material. There are two most common types of laser cleaning machines: One is CW fiber laser cleaning machine, another one is pulsed laser cleaning machine.CW fiber laser cleaning machine uses handheld clean head with continuous laser source. The advantage of CW cleaning machine is high cost performance. If you have low requirements for laser cleaning and only remove rust or thin paint of stainless steel, mild steel and iron, the cost effective CW laser cleaning machine can meet the requirements.CW laser cleaning machine powers support 1000W 1500W 2000W.Pulsed laser cleaning machine is equipped with pulse laser source and galvo clean head. If you have high-value products need to clean and without harm the base materials, that must be use pulsed laser cleaning machine system.Laser cleaners are designed for laser degreasing, laser paint removal, laser zinc removal, laser film removal, laser coating. Laser cleaning machines are mainly used for rust removal from metal surface, paint removal treatment, plating, coating removal, oil, stain, dirt cleaning, and rubber mold residue cleaning.

There are four main types of laser cleaning methods:

1. Laser dry cleaning method, which uses laser direct radiation to decontaminate.

2. Laser + liquid film method, that is, first deposit a layer of liquid film on the surface of the substrate, and then use laser radiation to decontaminate.

3. The laser + inert gas method, that is, while the laser is irradiated, an inert gas is blown to the surface of the substrate. When the dirt is peeled from the surface, the gas will be blown off the surface immediately to avoid re-contamination and oxidation of the surface.

4. After using the laser to loosen the dirt, clean it with non-corrosive chemical methods. The most commonly methods used in laser cleaning solutions are the first 3 ways. The fourth method is only seen in the cleaning of stone cultural relics. No matter what method of surface treatment is used, be sure to pay attention to laser safety. The laser cleaner is automated and easy to setup and use. The operation is simple, turn on the m achine to perform cleaning without chemicals, media, and water. It has the advantages of cost effective, manual adjustment of focus, high speed surface cleaning, and high cleanliness of the surface. It can remove resin, oil stains, stains, dirt, rust , coating, plating, paint on the surface of objects.

Handheld Fiber Laser Cleaning Machine Features:

1. Non-contact cleaning will not damage the surface of the substrates.

2. Precise cleaning to achieve precise location, precise size selective cleaning.

3. No chemical cleaning fluid, no consumables, safe and environmentally friendly in cleaning process.

4. It is easy to use, just power on, and it can be hand-held or cooperated with a manipulator to realize automatic cleaning.

5. The cleaning efficiency is higher than traditional cleaning tools to save time and labor cost.

6. The portable laser cleaning system is stable, almost no need of care and maintenance.

7. It can be used as a part of production lines for surface treatment in modern manufacturing.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Jul-22-2022