Overview

1. Definition

Laser cutting machines is a device that focuses the laser light emitted from the laser into a concentrated beam of high power density through the optical path system for cutting. It replaces the traditional mechanical knife with an invisible beam, which has the characteristics of high precision, fast cutting, not limited to cutting pattern restrictions, automatic typesetting to save materials, smooth incision, and low processing cost.

2. Classification

According to different cutting materials, laser cutting equipment can be divided into metal cutting machine and non-metal cutting machine; according to different lasers, it can be divided into CO2 laser cutting machine, YAG laser cutting machine and fiber laser cutting machine; according to different power, it can be divided into It is a low-power laser cutting machine, a medium-power laser cutting machine and a high-power laser cutting machine.

3. Industrial chain

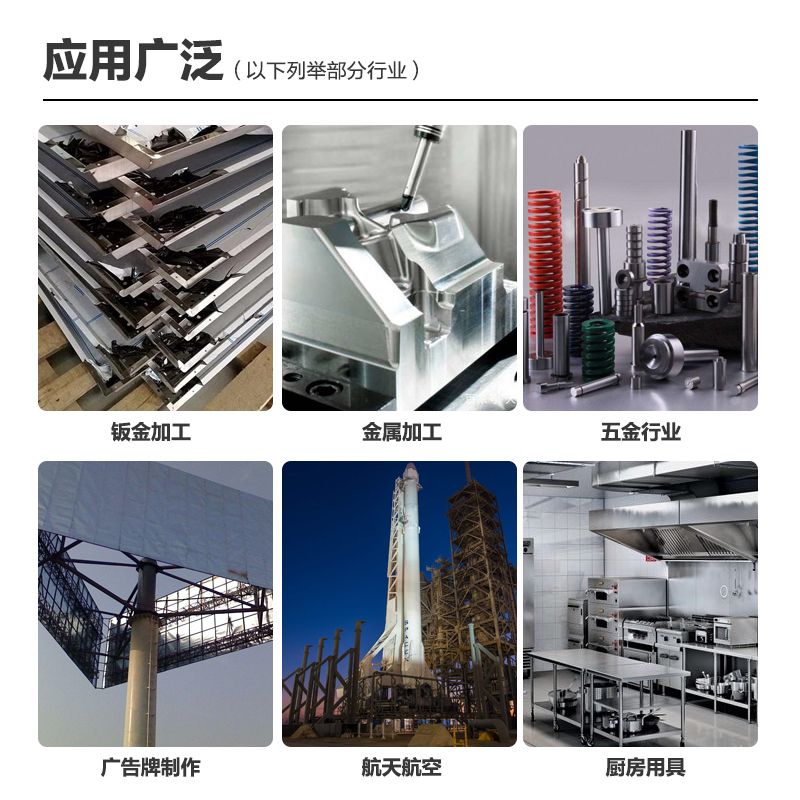

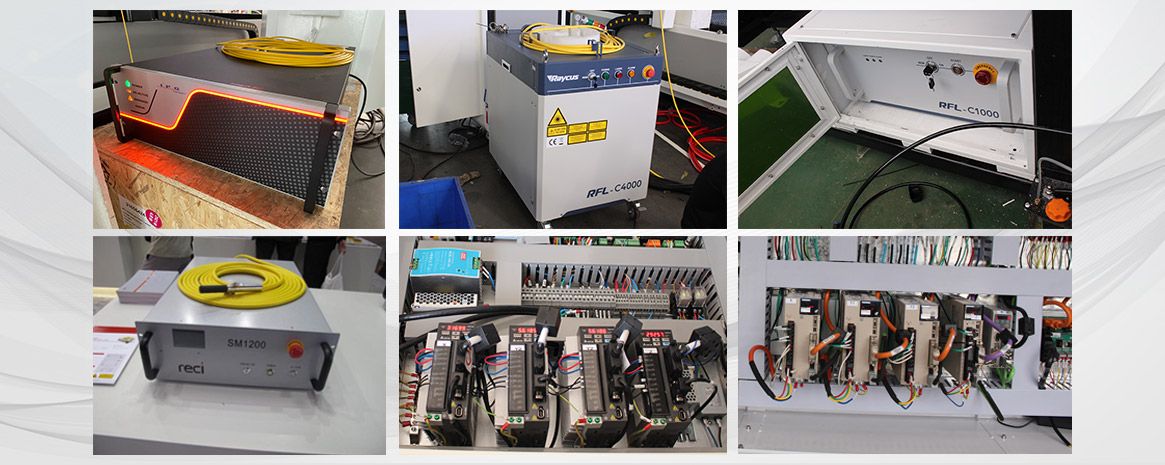

The upstream of the industrial chain of the laser cutting equipment industry is the component link, mainly including lasers, cutting heads, water coolers, air compressors, numerical control systems, bed bodies, etc.; the midstream is the production and supply link of laser cutting equipment; the downstream is mainly used in industrial manufacturing, communication Storage, automobile, aerospace military industry, light industry and other fields.

4. Development Trend

At present, the application industries of laser cutting involve automobiles, ships, aviation, nuclear industry, machinery manufacturing, steel, textiles, petroleum and laser processing centers. Laser cutting not only has many advantages and advantages, but also is the development of hard-core technology such as military and aerospace. The demand for laser cutting technology is increasing day by day. In addition to general-purpose laser cutting machines, high-speed high-precision laser cutting machines, large The demand for high-performance laser cutting systems such as thick plate laser cutting machines, three-dimensional CNC laser cutting machines, and non-ferrous metal laser cutting machines for aerospace is also increasing day by day. In the “Thirteenth Five-Year Plan”, it is clearly pointed out that my country will develop into a manufacturing power. Under the background of intelligent manufacturing and high-quality manufacturing, the industrial field will transform from traditional manufacturing to high-end manufacturing. The laser cutting industry will be the torrent of the times. The market scale continues to maintain a trend of rapid development. In addition, as the development trend of domestic industrial intelligence and processing precision continues to rise in recent years, the penetration rate of the domestic metal cutting machine market continues to increase, and the application fields continue to expand, and the industry has a good development prospect. In the future, with the continuous development of high value-added industries such as domestic new energy vehicles, aerospace, and rail transit, the domestic market demand for high-power laser cutting machines will continue to increase, and the laser cutting machine industry will move towards large-format, high-power, high-efficiency, high-efficiency The trend of intelligence continues to develop, and the industry has great potential for development.

Maintenance:

How to use and maintain fiber laser cutting machine? When using a fiber laser cutting machine to process objects, it is necessary to learn the equipment use and maintenance skills of the fiber laser cutting machine in order to better play the effectiveness of the equipment and maximize the efficiency of the equipment.

How to use and maintain fiber laser cutting machine:

1.Always check the steel belt and make sure it is tight. Otherwise, if there is a problem in operation, it may hurt people, and even cause death in serious cases. The steel belt seems to be a small thing, but it is a bit serious if something goes wrong.

2.Check the straightness of the track and the verticality of the machine every six months, and maintain and debug in time if abnormalities are found. If you do not do this, the cutting effect may not be very good, the error will increase, and the cutting quality will be affected. This is the most important thing and must be done.

3.Once a week, use a vacuum cleaner to suck off the dust and dirt in the machine, and all electrical cabinets should be tightly closed to prevent dust.

4.Each guide rail should be cleaned frequently to remove dust and other sundries to ensure that the equipment is normal. Racks should be wiped frequently and lubricated to ensure lubrication without sundries. The guide rail should be cleaned and lubricated frequently, and the motor should also be cleaned and lubricated frequently, so that the machine can move better and cut more accurately while the machine is moving, and the quality of the cut products will be improved. .

5.The dual focal length laser cutting head is a vulnerable item on the laser cutting machine. Long-term use will cause damage to the laser cutting head.

Fiber laser cutting machines need regular inspection and maintenance. If there is deformation or other forms, you should know that the laser cutting head has been damaged a little at this time and needs to be replaced. If it is not replaced, it will affect the cutting quality and increase the cost, and some products may need to be processed twice to reduce production efficiency. When the laser cutting head is purchased, it must be carefully checked to avoid problems when it is used.

Precautions for use:

1. Please ensure that the power socket is in good contact and the ground wire is reliably grounded!

2. Please ensure that the working voltage of the chiller is stable and normal!

Since refrigeration compressors are sensitive to power supply voltage, the normal working voltage of our standard products is 200~250V (110V models are 100~130V). If you really need a wider operating voltage range, it can be customized separately.

3. Mismatch of power frequency will cause damage to the machine!

Please use the 50Hz or 60Hz model according to the actual situation.

4. In order to protect the circulating water pump, it is strictly forbidden to run without water!

Before installing the new machine, the water storage tank is emptied. Please ensure that the water tank is filled with water before turning on the machine, otherwise the water pump is easily damaged. When the water level of the water tank is below the green (NORMAL) range of the water level gauge, the cooling capacity of the chiller will drop slightly. Please ensure that the water level of the water tank is within the green (NORMAL) range of the water level gauge. It is strictly forbidden to use the circulation pump to drain water!

5. Please ensure that the air inlet and outlet channels of the chiller are smooth!

The air outlet on the chiller should be at least 1250px away from obstacles, and the side air inlet should be at least 500px away from obstacles.

6. The filter screen of the air inlet must be cleaned regularly!

The dust-proof net must be removed and cleaned regularly, and the severe blockage of the dust-proof net will cause the chiller to malfunction.

7. Please pay attention to the influence of condensed water!

When the water temperature is lower than the ambient temperature and the ambient humidity is high, condensed water will be generated on the surface of the circulating water pipe and the cooled device. When the above situation occurs, it is recommended to increase the water temperature or insulate the water pipe and the cooled device.

8.This product is industrial equipment, please do not allow non-professionals to operate it.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Feb-17-2023