1.Prevent laser damage to human eyes

In the international laser classification, class 3 or 4 lasers are lasers that can be used for cutting. Operators are prohibited from looking directly at them. The power of scattered light should also not be underestimated. When operating a sheet metal fiber laser cutting machine, novices will be accustomed to paying attention to the good monochromaticity of the laser, small chromatic aberration in the fundus, and extremely low laser energy irradiation can cause damage to the cornea or retina, so as to avoid being stared at the laser and causing irreparable damage to your eyes.

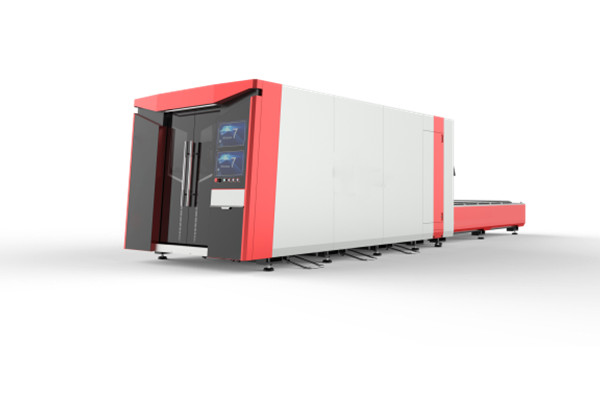

The closed type fiber laser cutting machine can isolate the laser from the operator to the greatest extent. After adjusting the various parameters and cutting the sample up to the standard, the side sliding door of the can be closed to perform fully enclosed cutting to avoid damage to the human body caused by the laser.

2.Reduce the harm of smoke and dust to people

The cutting method is thermal cutting, and a large amount of smoke and dust will be generated during the cutting process. Although fiber laser cutting machine with protective cover are generally equipped with dust extraction devices, the escape of smoke and dust is unavoidable, and it will inevitably cause pollution and harm to the working environment. The operator is in good health.

The enclosed structure, the smoke and dust used to escape is very small, or even negligible.

3.Avoid mechanical damage

Although the fiber laser cutting machine with cover does not use a blade but a laser as a processing tool, the probability of causing mechanical damage has been greatly reduced, but there is still no guarantee that there will be no accidents.It completely isolates the processing structure, processing material, carbonization device, etc. from the operator, minimizing the risk of accidents.

Post time: Aug-20-2021