To understand what are CNC Routers used for? we need to first understand what it the CNC router. CNC stands for “Computer Numerical Control” and as the name suggests, computerized or automated controls are used for the machining or subtraction of the layers of product which is often called work piece. CNC machining is done for various products which include wood, plastics Acrylic, stone and some metal materials like steels. A wide variety of customized parts can be constructed by using CNC machining.

CNC routers are similar to the CNC milling machines and other CNC machines of this category but they provide better efficiency and they also reduce the waste produced.

What can CNC Router Machine do

When it comes to the abilities of a CNC router machine, it does not mean that we are talking about the working of the CNC wood router and about the engraving methods and procedures that are adopted by the CNC router machine. Here it means that what type of materials can be engraved by using a CNC router machine. When we talk about the materials, it has a wide range of materials incorporated in itself that can lie in this domain.

Since CNC router machines are capable of engraving with the help of very hard and sharp tools, alongside wood and cardboard materials, CNC router machine is also capable for engraving acrylics, PVC board, 2 colour board, wooden board, rubber board. These all of the listed applications come in the range of polymers. Polymers have very low strength and also their elastic limit is very high. This means that machining of such materials is very easy and it can be done with the help of tools made up of high-speed steel or tool steel. Engraving on such polymeric materials such as acrylics, PVC boards, 2 colour boards and rubber board is being done since ages. They have a vast application in different sectors of industries and due to easy machinability of these materials, most of the work is done on CNC router machines. Below is a picture that shows the working and engraving is done on different types of polymeric materials including acrylic, PVC board, 2 colour cardboard and also the rubber board as well.

Now coming towards the ceramic materials, CNC router machines also feature for the engraving of very high strength and brittle materials as well. Some of the examples of such materials are density board, marble, glass and crystal. Since these materials have a very large strength so their machining is a little bit difficult. But it is not impossible and it is made easier by changing the process parameters and also the cutting tool applied. Since these materials are very much brittle, so the cutting or engraving that is used is made up of tungsten carbide. Tungsten carbide itself is ceramic and it has the potential to engrave many hard materials as well. Since this material is a bit expensive so it is only used in the engraving of ceramic and brittle materials. Below a picture shows the engraving procedures on different ceramic products.

Last but not the least, metals also find very popular applications in CNC router machines. Nowadays, most of the work is being done on metals. This is because of the reason that the new alloys have a very high strength to weight ratio. Due to this purpose, wood is being replaced in many applications of daily life. Now, as in the case of ceramics, the cutting tool is made up of tungsten carbide, in this case, the tool is either made up of tungsten carbide or it is made up of diamond. Since a lot of heat energy is released in the engraving process of metals and a lot of heat is released at the cutting point. So, the tip gets melted and to solve this problem, Diamond is preferred as its melting point is also very high. Some of the metals that are used for engraving by the CNC router machine are copper, aluminium, some steels generally low carbon steels etc. Below is a figure that shows the engraving of different metals by a CNC router machine.

Wood Sign Inscribed Letters

In these types of products, some sort of engraving is done on the wooden piece. Sharp tools are required for the cutting of the wooden material. Inscribing is one of the most common workings which is done by most of the industries from recent times. When the letters and shapes are inscribed, the final product seems to be quite opaque and the inscribing done in the final product can be differentiated easily. the picture below shows how the products look when the letters or shapes are engraved.

Wood Sign Raised Letters

In these types of products manufactured from CNC router machines, engraving is done but it is opposite to the case mentioned above. A large amount of material is removed in this case yet the final product also seems to be opaque. These types of products are also a speciality of CNC router machines. The image below shows the raised letters on the wood by CNC router machines.

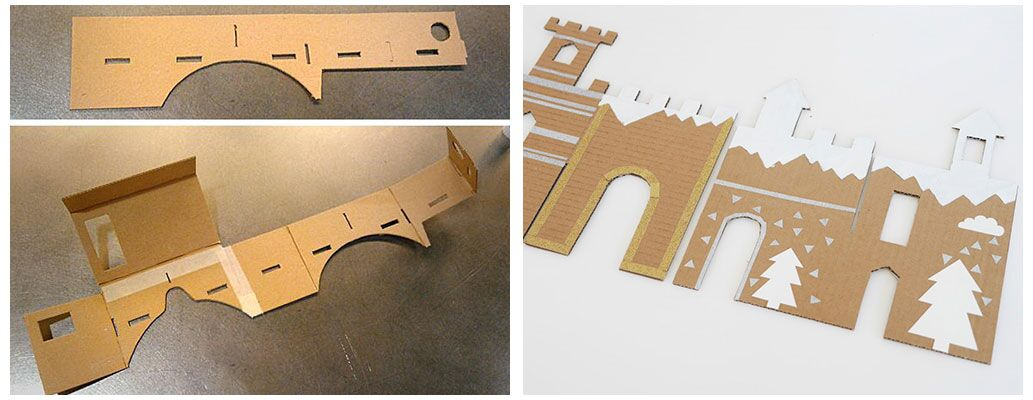

Cardboard Templates

For the manufacturing of cardboard templates, firstly the designs are made in software’s on the computers which also include all the dimensions. After that, the appropriate tools are selected which include Donek D4 drag knife and during this process, the feed speed of the machine is maintained at 100″/min with no revolutions per minute. The final product is like the one as shown in the picture below.

Engraving Granite

Apart from engraving on wood and non-ferrous metals, hard products could also be engraved using CNC router machine. Granite is considered to be one of the hardest metal with high strength. It can also be engraved but for this case, the tip of the cutting tool is usually made up of diamond. Since diamond is the hardest element known to us so Diamond is best for the machining of hard metals. The advantage is that when engraving is done with a diamond cutter, the final finishing is very smooth as shown below.

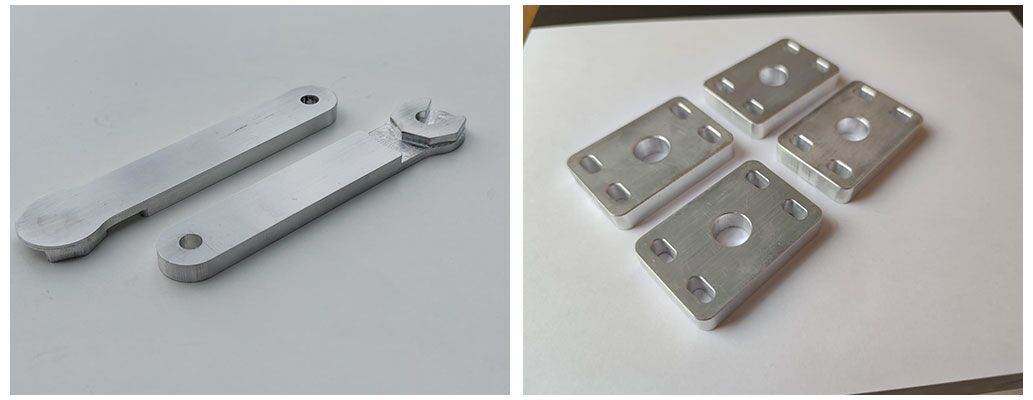

360 – Brass Bowtie

CNC router machine does not only work for wooden products only but it is also capable to manufacture metallic products but the condition is that the metals should be non-ferrous. Decorative products of aluminium, brass, copper and other various non-ferrous metals are produced in a large number by the CNC router machines but in this case, the parameters are quite difficult to handle. The processing speed is also kept low but the RPM is kept very high and parts per minute ratio of the product are also decreased. cutting blades are quite sharp in case of metals because of their high strength as well. The figure below shows some of the parts manufactured by CNC router machines.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Feb-06-2023