In the wood processing industries, the factories often receive the orders of customizing the wood products with different patterns and various sizes. And some woodworking fanciers would like to design the graphics or letters that they create. On such occasions, a CNC wood router, or specifically, a wood design machine can meet their needs.

What is the wood design machine?

The wood design machine is actually a kind of CNC wood engraving machine under the CNC Router. CNC router includes the CNC wood engraving machine, advertising engraving machine, and stone engraving machine. The CNC wood engraving machine has numerical control technology to allow users to use the software within the computer to design as required. Therefore, the CNC wood engraving machine is also named as the wood design machine.

The wood design machine is specially designed for the engraving, hollowing, milling, and other processing of wooden doors, cabinet doors, solid wood doors, embossed doors, and craft wood products. It has fast engraving speed, high precision, large bearing capacity, and long service life. CNC woodworking engraving machine is must-choice equipment for the wood door industry, cabinet industry, furniture industry, and other industries.

Wood design projects

As the name suggests, the wood design machine is mainly used for the CNC wood router projects. For example, there are the processing of various doors, windows, cabinets, craft wooden doors, paint-free doors, screens, craft fan windows, wave plate processing, and other furniture. It is not only suitable for many different kinds of CNC wood router projects. Additionally, the CNC wood router projects can also include the applications in the musical instrument industry, advertising industry, decoration industry, and the building model industry.

Wooden door and furniture decoration industry

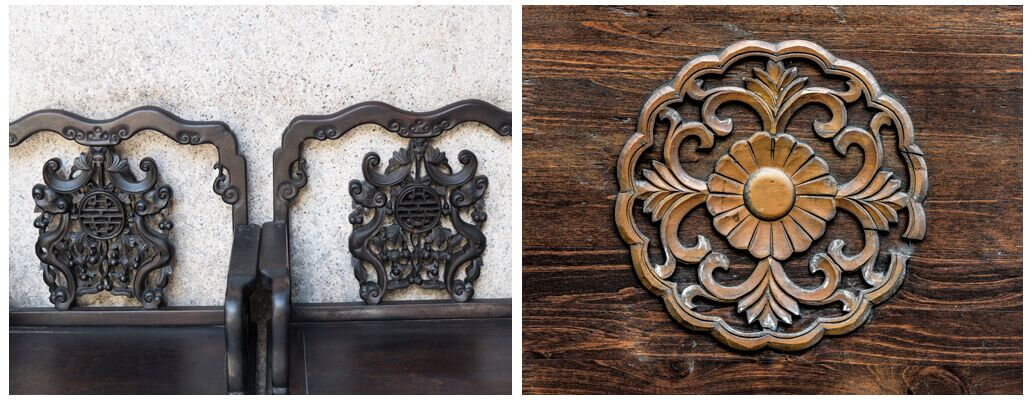

The wood design machine is mainly used for the processing of solid wood and composite doors, and cabinet doors. It can also be used as the wood carving machine for large-size plate carving, solid wood carving and milling, panel furniture carving, antique mahogany furniture carving, and solid wood art mural carving.

The following introduces some common wood products needing CNC routers in this industry.

Cabinet and closet door processing

In the woodworking industry, the production of cabinets and closet doors is one of the most popular applications of CNC router. The manufacturers of wood cabinets prefer to use CNC wood engraving machines to reduce the costs and increase production quantity. In addition, these highly effective CNC routers are very popular in processing drawers, shelves, table boards in different sizes at the same time.

Chairs, sofa legs, and stair handrails

CNC wood design machine improves production time is are no longer limited to mold processing and plane engraving. Some factories are using CNC routers as a production method for manufacturing chairs of various designs. Due to the digital characteristics of the numerical control system, the current digital curve model of the chairs is designed by using computer software. The software supports the 3D format, which can be modified on the computer according to the woodworking processing needs of customers.

The CNC router is the numerical control technology instead of a traditional CNC machine. Therefore, the users can design the engraving curves and set up processing parameters of the chairs, sofa legs, and stair handrails. And then they can produce the shape as designed or as required by the customers. The use of the CNC wood design machine is more a creative and intelligent machining process for the engraving and cutting of the chairs. The CNC wood router also inspires manufacturers to create different kinds of shapes and designs.

Wooden crafts processing industry

Clock and watch frames, craft photo frames, thin aluminum plate crafts engraving, milling and engraving, electric appliance cabinet boards, sports goods.

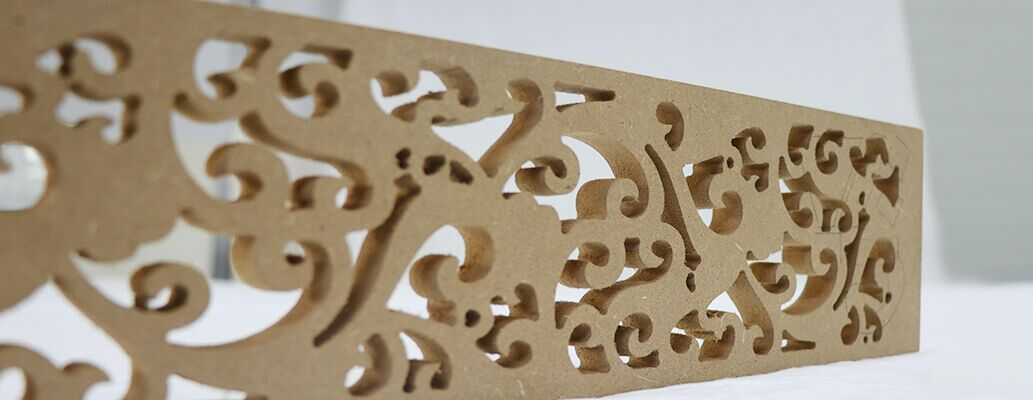

Advertising and decoration industry

The CNC wood router can also be taken as the wood design cutting machine in the advertising industry. The users can design the cutting patterns to cut acrylic boards, aluminum-plastic panels, decorative materials, and MDF boards.

EVA processing industry

The wood design machine can cut and engrave EVA materials, such as, EVA material packaging tools, medical packaging, and electronic products.

Released by Jinan APEX Machinery Equipment Co., Ltd.

Post time: Dec-13-2022