Fiber laser cutting machine is a kind of CNC cutting machine. Its principle is to melt and evaporate the workpiece by the energy released when the laser beam is irradiated on the surface of the workpiece, so as to achieve the purpose of cutting and engraving. According to the different power, fiber laser cutting machine is divided into two types: small and medium power and high power. Now APEX will give you a brief introduction.

The fiber laser cutting machine is mainly composed of two parts, one is the CNC console, and the other is the machine tool. We can input the drawings to be processed through the CNC console, and after the operation, the instructions will be transmitted to the processing machine tool, and the processing machine tool will process the desired sheet metal pattern according to the instructions. Its advantages are that it does not require mold opening and tools, has no stress on the product, has high precision, fast cutting, is not limited to cutting pattern restrictions, automatic typesetting saves materials, smooth cuts, and low processing costs.

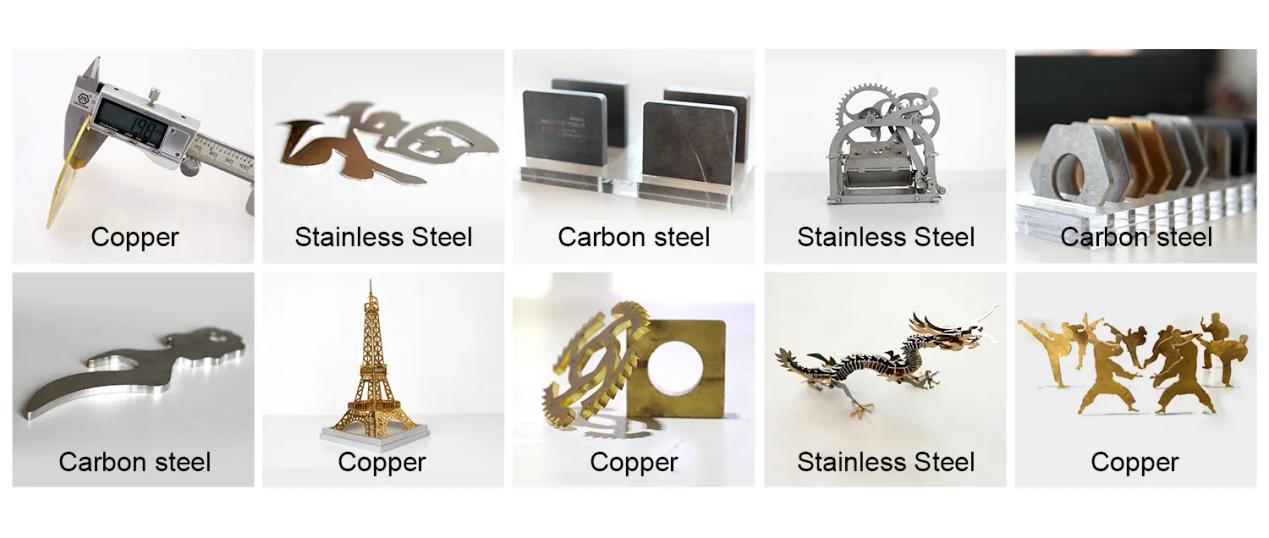

Therefore, it is especially suitable for the processing of sheet metal industries such as chassis shells, kitchen cabinets, and precision parts. Almost all industries involved in metal cutting can be applied.

The advantages of choosing laser cutting are as follows:

1. Good cutting quality

Narrow slit (generally 0.1-0.4mm), high precision (generally, the hole center distance error is 0.1-0.3mm, and the contour size error is 0.1-0.4mm)

2.Fast cutting speed and high efficiency.

The fiber laser cutting machine is non-contact processing and has small inertia, so its processing speed is fast. And because of the use of numerical control system, when using advanced CAD/CAM software programming, it is time-saving and convenient, and the overall efficiency is very high.

3. Small heat-affected zone, almost no deformation

The heat and temperature of the laser irradiated processing part is very high, but the irradiated light spot is small, and the beam moves fast, so the heat-affected zone is very small.

4. Clean, safe and low labor intensity

Due to the high degree of automation of laser cutting, it can be fully enclosed, pollution-free, and low-noise, which greatly improves the working environment of operators.

5. It can be used for cutting almost any metal material

The laser has high brightness, good directionality, and a small spot after focusing. It can generate extremely high energy density and power density, enough to melt any metal, and can also process non-metals. It is especially suitable for processing materials with high hardness, high brittleness and high melting point that are difficult to process by other methods.

6. Not susceptible to electromagnetic interference

Laser processing does not have to be carried out in a vacuum like electron beam processing. Laser processing is carried out in the air, sometimes using appropriate auxiliary gas, and the beam transmission process in the air is not disturbed by electromagnetic fields.

7. Laser cutting has good economic benefits

Especially for materials that are difficult to process by other traditional methods, the advantages of laser cutting are more obvious, because the processing cost of laser cutting is less affected by material changes.

8. Energy saving and material saving

The energy utilization rate of the laser beam is 10 to 1000 times that of conventional thermal processing. Since the slit of laser cutting is very narrow, and it is processed by numerical control, it can save materials by 15% to 30%.

Post time: Jul-20-2023