CNC Machines

-

1000W/2000W/3000W Fiber Laser Metal Fabricator

Fiber laser cutting machine adopting world famous Germany IPG fiber laser source and Raycus laser source,Raytools cutting head and dynamic focus system, it can cut and punch different kinds of metal material with high precision and high speed. Since laser is transmitted by fiber , it is no need to maintenance or adjusts the laser optical path , it greatly reduces the machines fault rate and prolongs the working life. Large format cutting area meets the demands of various kinds of metal processing .

-

Mixed Laser Cutting System for Metal and Non-metal

This machine can cut and engrave on the acrylic, the max thickness can cut and engrave on the acrylic is: 20mm. We have many size of laser machine, as working size: 1300x900mm, 1300x2500mm, 600x900mm, 1400x1000mm 1600x1000mm and so on. Laser tube has 60w, 80w, 100w, 120w, 150w, using the Beijing RECI, or Chengdu Weegiant, having the honey nest table and the blade table.

-

Hybrid CO2 Laser Cutter for Metal and Wood

Main features

1.Imported stepper motor and drive systems

2.Domestic reci lasers (150W/ 180W/ 200W) optional, Adopted imported linear guide rail

3.Large LCD display subtitles, humane button control panel

4.Optical system using the full import of laser lens system in Singapore

5.High strength stainless iron or aluminum honeycomb floor slats optional knife

6.Ruida controller system–6332 model -

1390 Metal and Nonmetal Mixed Laser Cutting Machine for Sale

This machine can cut and engrave metal and non-metal, the max thickness can cut and engrave on the acrylic is: 20mm. We have many size of laser machine, as working size: 1300x900mm, 1300x2500mm, 600x900mm, 1400x1000mm 1600x1000mm and so on. Laser tube has 60w, 80w, 100w, 120w, 150w, using the Beijing RECI, or Chengdu Weegiant, having the honey nest table and the blade table.

-

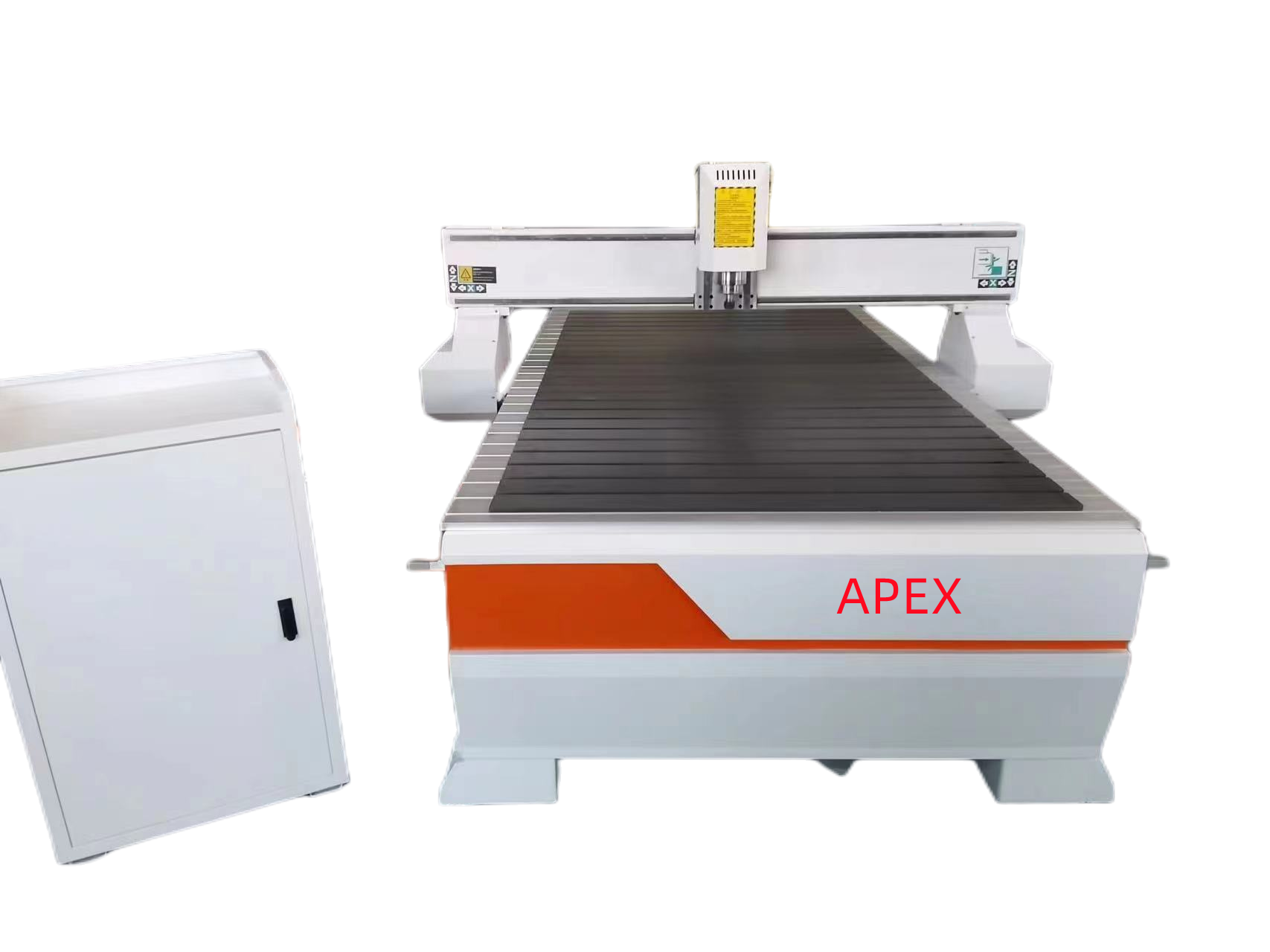

1325 4×8 4 Axis CNC router 3D wood carving machine

1325 4×8 4 Axis CNC router 3D wood carving machine has a popular table size of 1300*2500mm(4x8ft), and is the best selling size in our 4 Axis CNC router machine. 4 Axis cnc is powerful and can do anything that basic 3 Aixs machine can do. if your workpieces need 3D carving, 4 Axis cnc machine is your essential need.

-

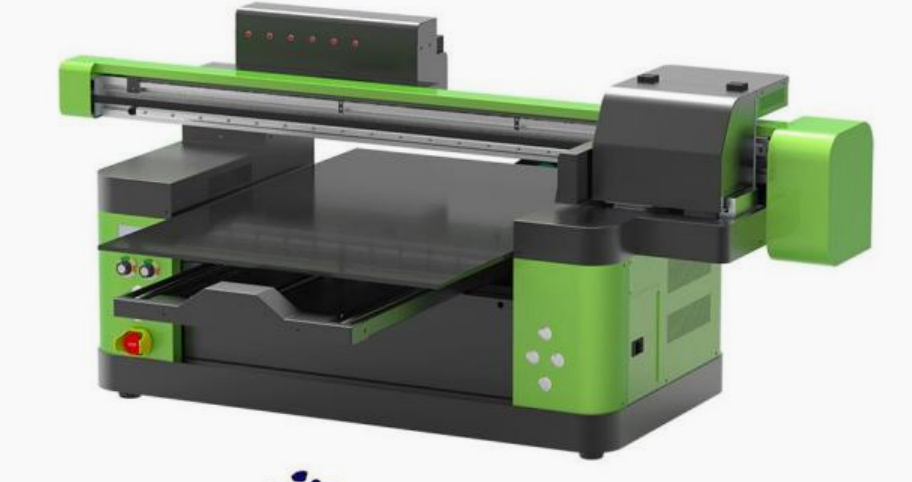

6090 Portable UV Printer Hot Selling New Model

Work Process1. Pre-treatmentFor materials such as metal, glass and some of the acrylics need to have pre-treatment before print.Put the coating on by brush or non-dust cloth, leave for 1-2 minutes to dry.2. Check the distance between the print head and the flatbedDistance about 2-3mm. (The thickness of a coin)3. Print positioning frameSelect the PRN position frame in PrintEngine, click print.4. Set the objectsPut the objects into the positioning frame, check the height again.5. PrintFind the positioning frame & Image PRN and print. -

1000W Best Handheld Laser Welder for Aluminum& Stainless Steel

This is a hand-held laser welding machine that can weld any position and any angle of the workpiece. The operation is flexible and convenient. It can not only realize outdoor welding, but also apply to various complicated welding seams and spot welding of various devices.

-

100W Laser Cleaning Machine Handheld Laser Cleaner for Metal Laser Rust Removal

Cleaning metal with a laser cleaning machine is considered as the most reliable and effective way to remove the dust, rust, oil stain, and grease on the metal surface. This handheld laser cleaning machine adopts stable laser source and high-quality laser beam. It can remove multiple types of contaminants from aluminum, steel, carbon steel, and other metal.

-

The Most Popular 1325 Linear ATC CNC Router for Sale

This 1325 ATC CNC router is one of the most classic and popular CNC among the tool change engraving machines. It adopts the linear tool change mode with a fast tool change speed, and the tool change can be completed within a few seconds without any people’s operation, which greatly improves productivity.

-

Best Price Jewelry Welding Machine Precision High Speed

Low production cost. Due to the low power of the welding machine, the welding time is short. Therefore, electric energy can be saved. Compared with flash butt welding, it saves about 80% to 90% of electric energy. The processing cost can be reduced by about 30%. Can weld dissimilar steel and dissimilar metals.

The advantages of laser spot welding machine for gold and silver jewelry can be adjusted in a wide range, such as energy, pulse width, frequency, spot size, etc., to achieve various welding effects. The parameters are adjusted by the control rod in the closed cavity, which is simple and efficient. Imported ceramic concentrating cavity is adopted, which is resistant to corrosion, high temperature, high photoelectric conversion efficiency, life of concentrating cavity (8-10 years), and life of xenon lamp more than 8 million times. The use of the most advanced automatic shading system eliminates eye irritation during working hours. It has 24-hour continuous working ability, stable working performance of the whole machine, and maintenance-free within 10,000 hours. Laser welding humanized design, in line with ergonomics, long-term work without fatigue.