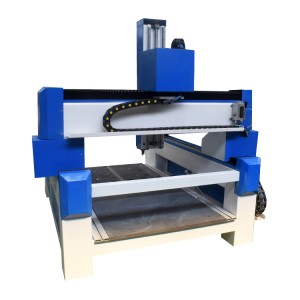

2021 new model CNC Router PTP for Wood Furniture Routing, Drilling, Cutting, Milling

PTP CNC router machine is suitable for routing, drilling, cutting and milling panel furniture, wooden crafts, solid wood furniture, wood doors, cabinet, kitchen doors, etc.

Demonstration Video

Product Descriptions

APEX1325C PTP CNC router advantages:

Function: It is suitable for processing diversification and complex products, entire function: routing, pneumatic drill, cutting, side milling, side drilling, side cutting, etc. It can accomplish double station four areas processing, one station is machining, the other is up-down loading, improving the efficiency and capacity greatly.

Construction: The whole machine table adopts high strength thick steel pipe welded. Whole working table cast by resin sand. The annealing and other heat treatment methods ensure that the whole structure is tested to the limit for sturdiness and reliability.

spare parts: Features world top class mechanical and electronic components, e.g. German rack and pinion, Taiwan rail and ball screw, Taiwan reducer, French Schneider electrical components, which guarantee stable performance and high quality.

Precision: Excellent spare parts, accurate precision detection instrument, which make sure the machine with perfect location and working precision.

High-speed: Adopt reducer direct design, high torque, high energy, X axis dual motor drive, runs smoothly with high efficiency.

Table: Vacuum workable fitted with aluminum alloy bars and suction cups can be set flexibly according to the size of wokpiece, and convenient to unload workpiece.

Tool magazine: With one 8-slots Carousel tool changer, tool changes to be performed quickly.

APEX1325C PTP CNC router machine features:

1. Adjustable Vacuum Pump Suction Cups.

2. Boring Unit & Saw Blade Unit optional.

3. Intelligence OSAI or Syntec control system.

4. Japan Yaskawa Servo motors.

5. Strong heavy duty Mahine Body design.

6. Smart Feet-Touch Sensor Switch.

7. Disk Type 8pcs Auto Tool Changer SYSTEM.

8. Adopt Italy HSD Boring Head, it has vertical boring head+horizontal boring head+saws. So it is appropriate for side working, like side drilling, slotting, milling, etc .

9. Single arm type, it is more convenient for you to loading material.

10. Double working position design. One side is machining, the other side is up-down loading, improving the efficiency and capacity greatly .

11. Fixed type Pneumatic cylinder be used for correct the carved wood