Short Lead Time for Eastwood Plasma Cutting Table - Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe – Apex

Short Lead Time for Eastwood Plasma Cutting Table - Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe – Apex Detail:

Fiber laser cutting machine has dual function for cutting sheet metal/metal plate and metal tube/metal pipe, such as steel, aluminum, alloy, titanium, copper, brass, iron and other metal materials.

Product Descriptions

Features and advantages of Dual-Purpose fiber laser cutting machine for Metal Sheet, Tube and Pipe:

1. The machine is equipped with an exchanged double working platform. While working on one table, the other platform can load and unload the sheet workpiece;

2. Auto feeding model is driven by frequency conversation drive-down motor, high transmitting power and safety factor, enabling stepless speed adjustment for different operating frequencies;

3. Pipe cutting machine is specially designed for metal pipes, metal tubes;

4. Imported high precision transmission device which is perfectly work with servo system, thus it can make sure cutting precision and efficiency;

5. Higher cutting quality and efficiency ,cutting speed is up to 120m/min with appearance and beautiful cutting edge.

Technical Parameters of Dual-Purpose Fiber laser cutting machine for Metal Sheet, Tube and Pipe:

| Model | APEX3015 |

| Laser Cutting Area | 1500*3000mm |

| Laser Power | 1000W (2000W, 3000W, 4000W, 6000W, 8000W for option) |

| Max Cutting Speed | 120m/min |

| Repeated Positioning Accuracy | 0.02mm |

| Power Requirements | 380V/50Hz/60Hz |

| Machine Weight | 8000KG |

| Machine dimension | 8950*3650*2350mm |

Applications of Dual-Purpose Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe:

Applicable materials: stainless steel, carbon steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron and other metal materials.

Applicable industries: Kitchen appliance, electric control box, high-resolute device, mechanical equipment, electrical equipment, lighting, posters, auto parts, display equipment, hardware and other metal processing.

Dual-Purpose Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe Projects:

Package for Dual-Purpose Fiber Laser Cutting Machine:

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard protective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Pre-Sale Service for Dual-Purpose Fiber Laser Cutting Machine:

1. Free sample cutting service:

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

2. Progressing Solution Design:

According to customer

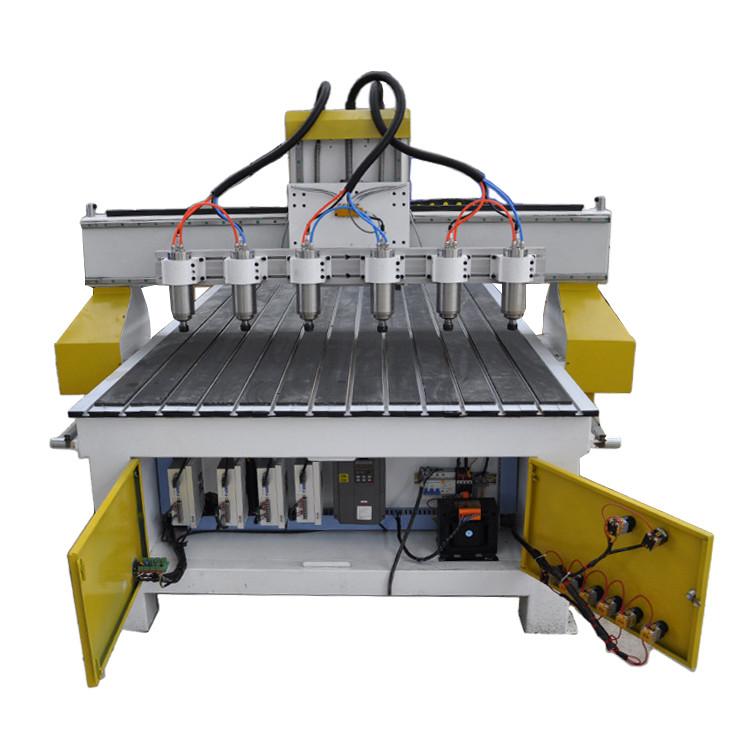

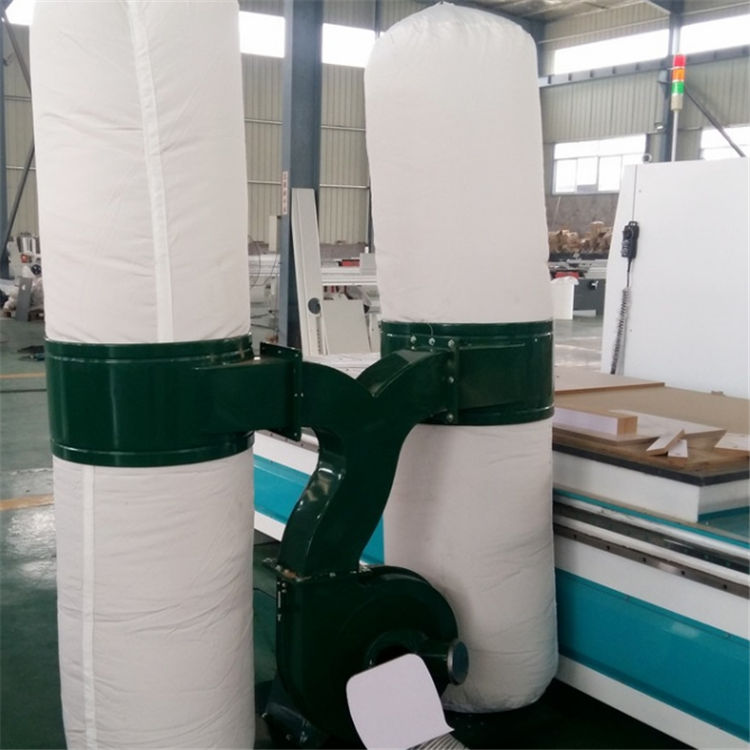

Product detail pictures:

Related Product Guide:

We have state-of-the-art equipment. Our products are exported for the USA, the UK and so on, enjoying a fantastic status among the clients for Short Lead Time for Eastwood Plasma Cutting Table - Fiber Laser Cutting Machine for Metal Sheet, Tube and Pipe – Apex , The product will supply to all over the world, such as: Mecca, Uganda, Israel, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we supply, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and thorough parameters and any other info weil be sent for you timely for the inquiries. So make sure you get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we have been going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.