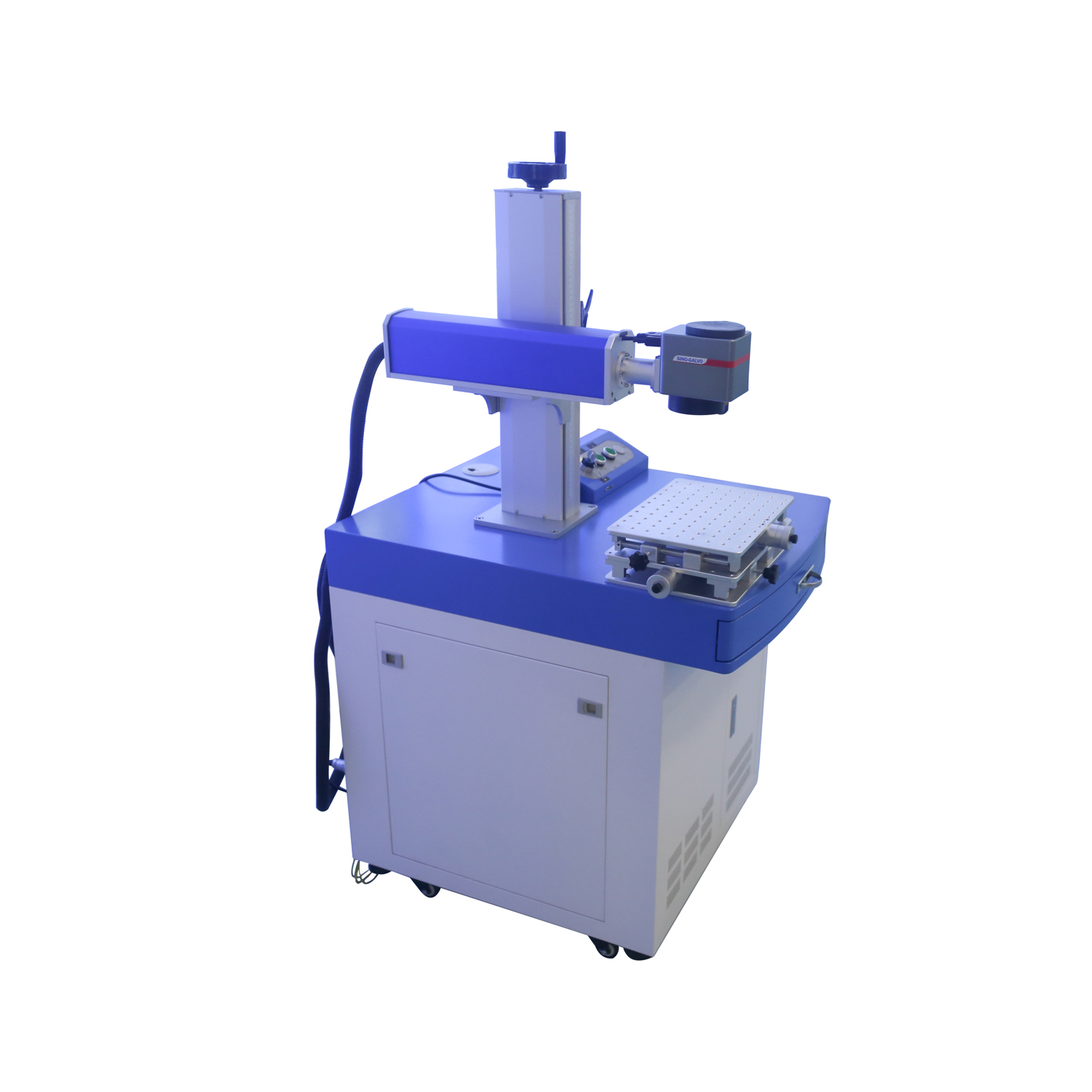

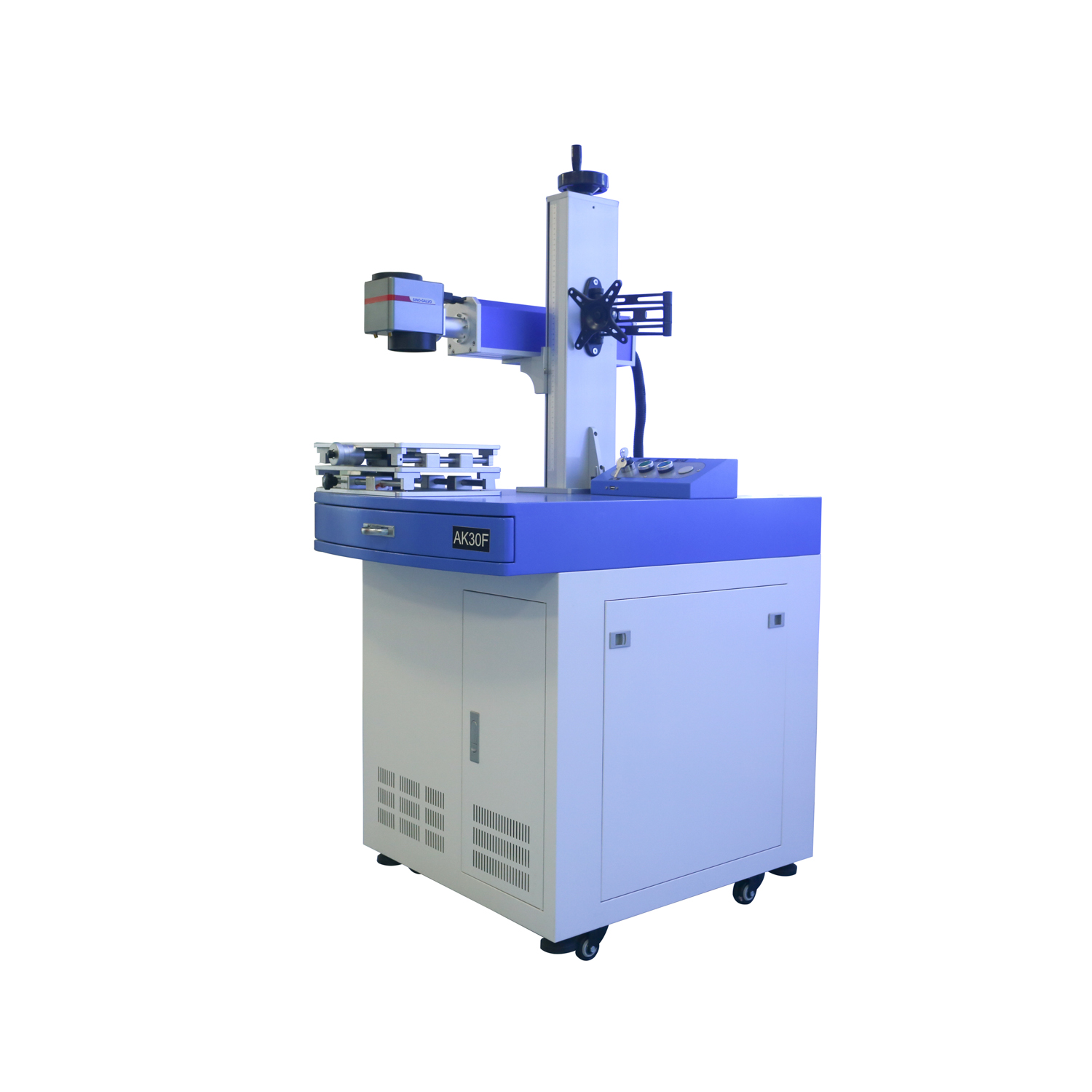

UV Laser Marking Machine for Plastic, Silicon, Glass, Ceramic

Desktop UV laser marking machine adopts Ultraviolet (UV) laser, which is a kind of cold light. UV laser marking machines are mainly used for plastics, including PP (polypropylene), PC (polycarbonate), PE (polyethylene), ABS, PA, PMMA, silicon, glass and ceramics.

Product Descriptions

Ultraviolet (UV) laser is a kind of cold light which is mainly used in super precise marking and engraving, particularly suitable for food, pharmaceutical packaging material marking, micro punching, glass high-speed dividing, silicon wafer complex graphics cutting, etc.

Features and Advantages of UV laser marking system:

1. UV laser marking machine adopts 355nm pumped UV laser device, so as to get smaller diameter of focusing spot and fine marking effect.

2. The metal absorb UV higher than infrared and therefore more suitable for UV laser marker marking on metal and glass materials compared with infrared pump machine.

3. Narrower pulse width of UV laser makes a shorter time of processing on materials, thus the materials avoid being deformed or burnt due to thermal.

4. With smaller heat affected area and more beautiful marking effect, our products UV laser marking system can meet customer with higher marking requirements.

5. The UV laser machine is equipped with safety shield, which can effectively isolate the purple radiation, to ensure the safety of UV laser marker operators.

6. UV laser machine is equipped with a professional water cooling machine, air-cooled water circulation cooling, with water-cooled high efficiency and air-cooled small size.

7. Low energy consumption, environmentally friendly, no consumables. Little affect area, no heat effect, without material burned problem.

Technical Parameters of UV Laser Marking System:

| Model | APEX-3U |

| Laser type | Ultraviolet laser |

| Laser wavelength | 355nm |

| Output power | 3W |

| Pulse length |